A new generation of zinc primers

As part of our project, we developed zinc primers with low zinc content which exhibit protective properties comparable or superior to traditional high-zinc primers, even in marine environments

Project title

Project title

A new generation of zinc primers with enhanced performance and improved corrosion preventive and environmental properties

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Polish Corrosion Society

Name of programme

Name of programme

International programmes

Competition

Competition

22nd competition within the CORNET initiative

Project value

Project value

PLN 1,576,752.00

Project partners

Project partners

International project partners: Forschungsgesellschaft für Pigmente und Lacke e.V. (FPL), Fraunhofer Institute for Manufacturing, Engineering and Automation IPA, Germany, Polish project implementers: Łukasiewicz Research Network – Institute for Engineering of Polymer Materials and Dyes, and the Road and Bridge Institute

Project delivery period

Project delivery period

01 July 2017 – 31 August 2019

View the results of our work

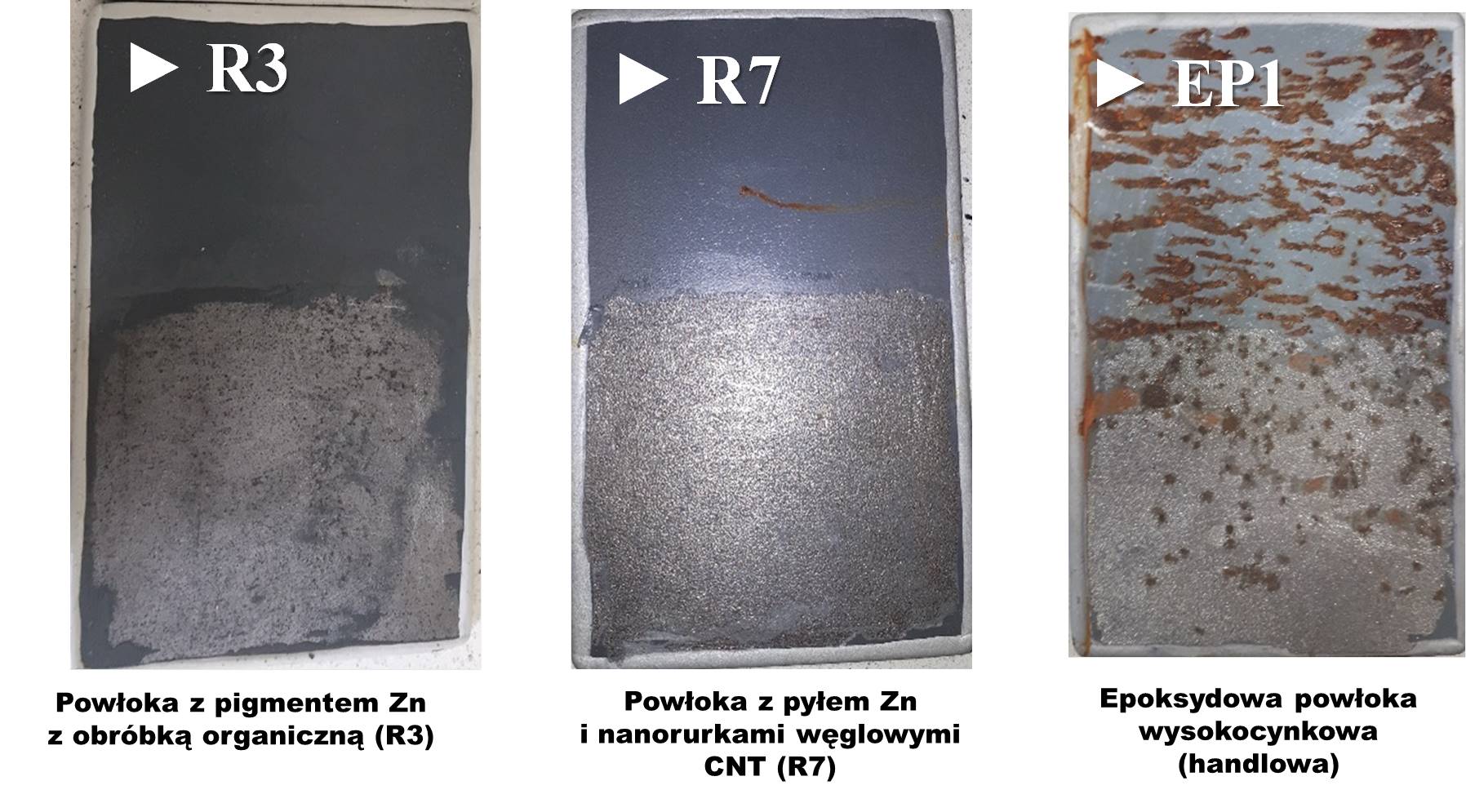

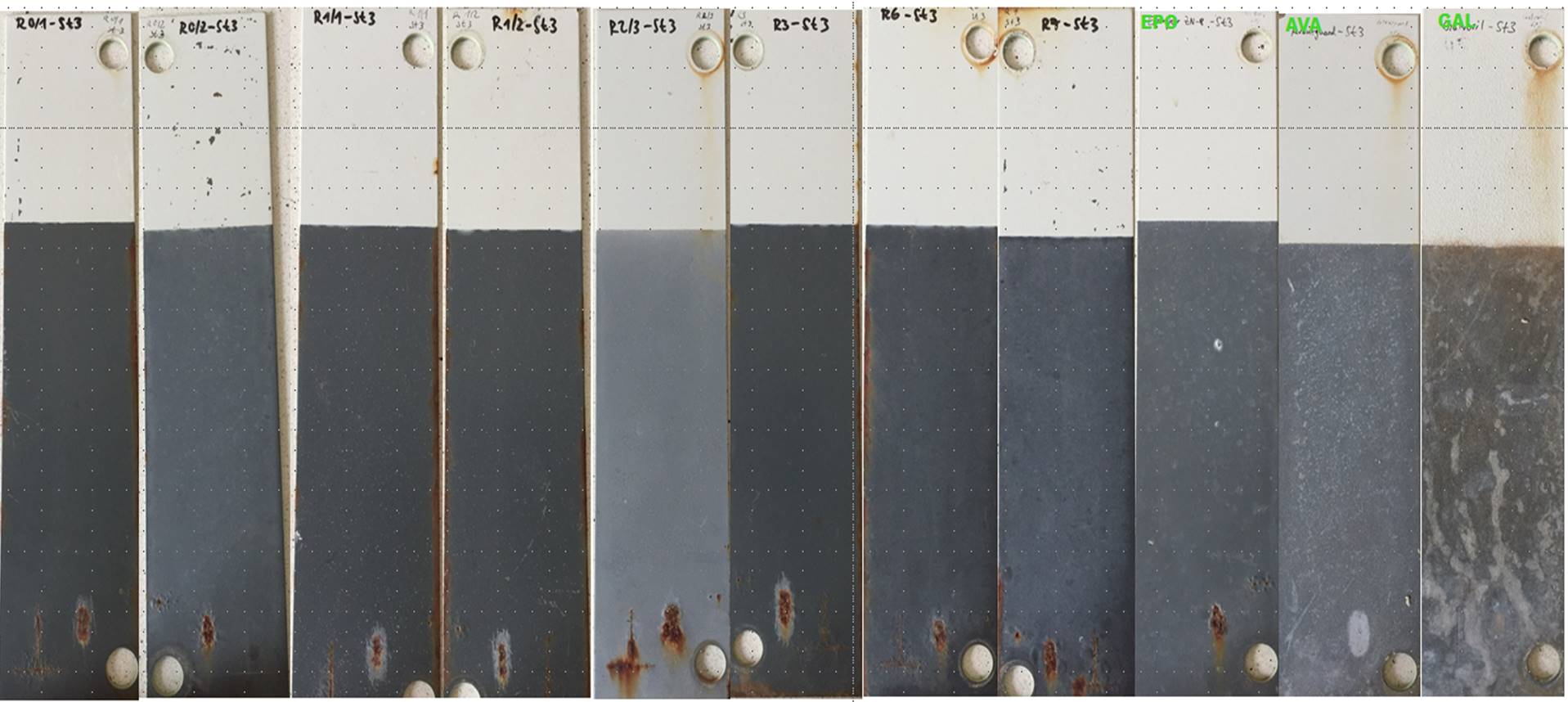

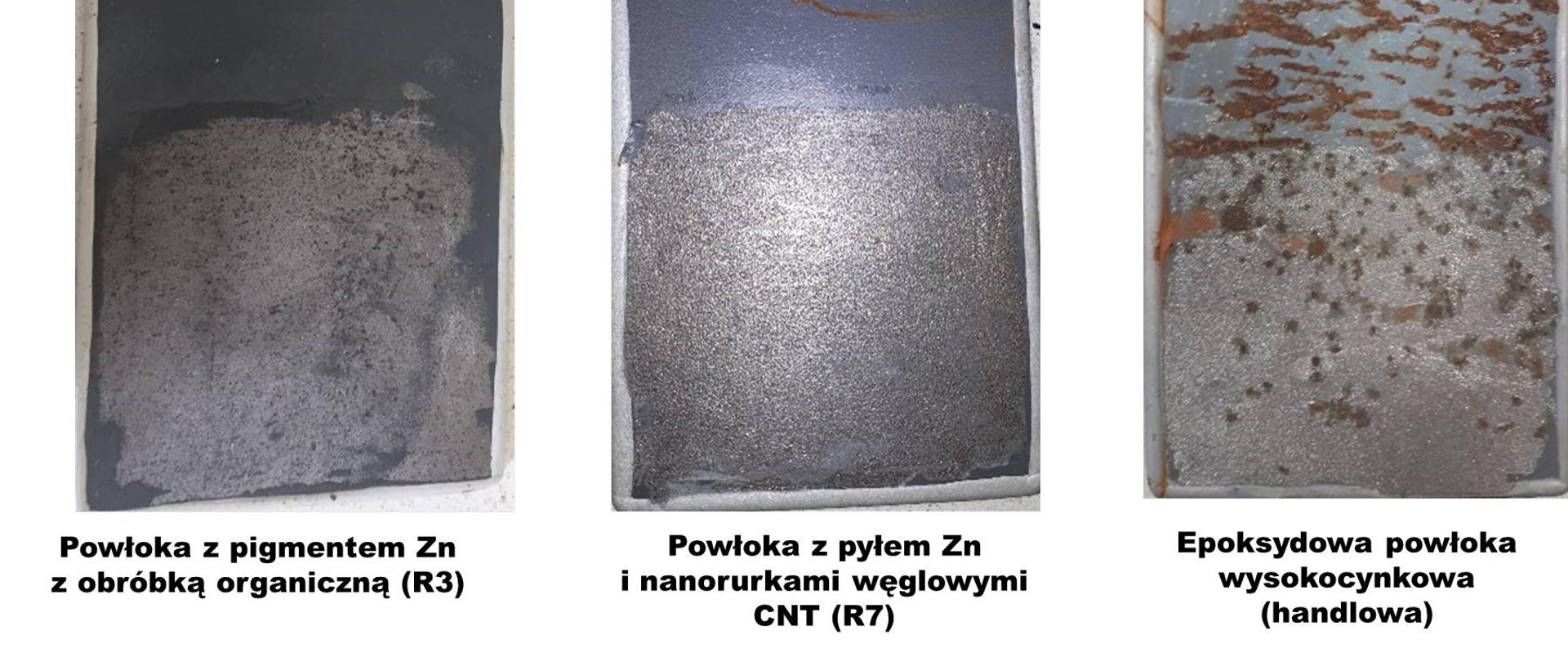

Sample comparison

For protection against the corrosion of steel structures in typical three-layer corrosion preventive systems, it is very common to use high-zinc primer paints as steel protectors and barriers. As part of our project, we developed zinc primers with low zinc content which exhibit protective properties comparable or superior to traditional high-zinc primers, even in marine environments. We obtained epoxide primers with zinc pigments in which the zinc content was reduced to about 50% in the dry layer. In our paints we used zing pigments of various shapes (dust, flakes), Zn pigment mixtures of various particle shapes and sizes, zinc dust with superficial chemical treatment, compounds from the group of bifunctional organosilanes, zinc-tin alloys and zinc-magnesium alloys, and mixtures of zinc dust with carbon nanotubes and graphene. In Poland, corrosion preventive paints account for about 30% of the overall market for coating products, and this sector is important for the economy due to losses caused by corrosion, which are estimated at a whopping 8% of Poland’s GDP. The reason why it is important to expand the range of environmentally friendly high-performance corrosion preventive paints is that they provide more durable protection. And the reduced zinc content addresses the dwindling resources of this metal. The project brings social benefits such as reduced environmental pollution with the products of zinc corrosion (water, soil), improved appearance of structures and extended durability of protection (which means longer times between repairs, and less CO2 emissions, less social disruptions and lower financial expenditures). The project also provided new insights into the protective mechanism of layers containing zinc pigments in amounts lower by more than a half compared to traditional high-zinc primers, which represents an important scientific contribution in this field.

Have you managed to develop a market-ready product or technology?

The project delivered corrosion preventive primers with reduced zinc content along with a (laboratory-based) technology to manufacture them. It is a market-read technology which can be employed by manufacturers of coating products (both those producing traditional high-zinc primers and those planning to start manufacturing this type of paints). SME User Committee companies have direct access to project results and formulas.

What was the pathway to the commercialisation of results?

The project results are yet to be commercialised – one of the paint manufacturers, a Supporting Member of the Polish Corrosion Society (PSC) and a Member of the SME User Committee, is interested in deploying the technology to manufacture one of the formulas – additional studies are underway on the specific formula alternative which meets that producer’s requirements. After a presentation of the project results at a PSC webinar held on 17 November 2020, another producer of coatings expressed interest in paints with low zinc content. As study results are being published widely, we hope this is only the beginning of market interest in our formulas.

Have you encountered difficulties with the commercialisation and if so, how did you manage to overcome them?

As already mentioned, we commenced additional studies for the selected formula and preliminary talks about deploying this technology at one of the coating manufacturers in Poland. Regrettably, the SARS-CoV-2 pandemic caused by coronavirus has significantly slowed down our work and talks.

How was the issue of intellectual property in the project resolved?

The rules governing access to research results are governed by a consortium agreement. The solution is accessible for all interested parties at market terms. One of the zinc primer formulas we developed is the subject of patent application P.428816 – “Two-component epoxide corrosion preventive paint”.