Advances in welding technology

Innovative electrode clamp control system in the resistance welding process

Project title

Project title

An innovative method of controlling a servo pressure system in the techniques of joining thin-walled metal elements

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Welding Institute (until March 31, 2019) - currently (from April 1, 2019): Łukasiewicz Research Network – Instytut Spawalnictwa

Name of programme

Name of programme

SMART GROWTH OPERATIONAL PROGRAMME

Competition

Competition

TANGO I

Project value

Project value

PLN 1 150 000

Funding value

Funding value

PLN 995 000

Project delivery period

Project delivery period

1st Jun 2015 – 30th Apr 2018

Meet our team

View the results of our work

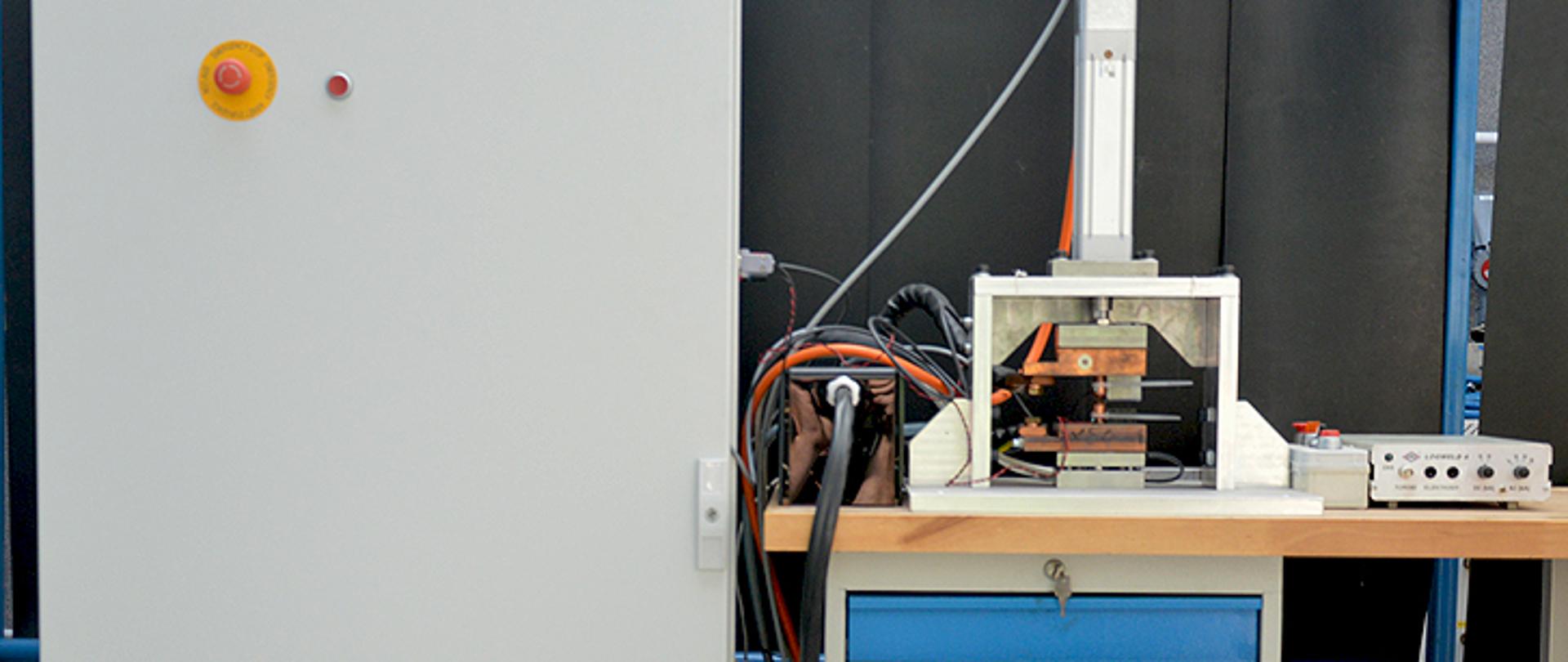

Examples of resistance welding technology comparing the process for two different electrode clamping systems of a resistance welding machine, i.e. the pneumatic SPD clamping system - a conventional system and the electromechanical clamping system SED - an innovative system developed under the TANGO project:

![Comparison of the results of the experiment and FEM calculations of welding full humps, e.g. nuts, for SPD (a1 and a2) and SED (b1 and b2) [1]](https://www.gov.pl/photo/3f7f3eb7-fdff-439f-86b2-6439991a68d1)

![Comparison of the results of the experiment and FEM calculations for welding metal sheets with an embossed hump for SPD (left side) and SED (right side) [2]](https://www.gov.pl/photo/fc9d6f2a-dfef-468a-80bc-fbf2ac1c41e9)

![Comparison of the results of the experiment and FEM calculations for welding metal sheets with an embossed hump for SPD (left side) and SED (right side) [2]](https://www.gov.pl/photo/abaca005-cf03-4981-a100-2e758ad1db56)

![Results of modeling aluminum rod welding with the use of electrode clamping system: a) pneumatic and b) electromechanical [3]](https://www.gov.pl/photo/7344c3cf-e600-4f8c-a13a-00001dae0fb9)

![Optimization of welding using the electromechanical clamping system SED as opposed to the pneumatic clamping system SPD [4]](https://www.gov.pl/photo/83e0e5c4-0217-4ac7-9748-6eabc84f0f59)

[1] Mikno Z., 2018, Projection Welding of Nuts Involving the Use of Electromechanical Electrode Force. „Intl. Journal of Advanced Manufacturing Technology”, 99:1405–1425, https://doi.org/10.1007/s00170-018-2525-5

[2] Mikno Z., 2016, Projection Welding with Pneumatic and Servomechanical Electrode Operating Force Systems, „Welding Journal” (Welding Research) 2016 vol 95. August, pp. 286-299.

[3] Zygmunt Mikno, 2019, Cross-wire projection welding of aluminium alloys – pneumatic and electromechanical electrode force system, „The International Journal of Advanced Manufacturing Technology”, DOI: 10.1007/s00170-019-03443-5.

[4] Mikno Z., Stępień M., Grzesik B., 2017, Optimization of resistance welding by using electric servo actuator, „Welding in the World”, Open Access 21 February 2017, DOI:10.1007/s40194-017-0437-x.

What problem is addressed by the project?

The problem that we solved in the project is related to the testing and implementation of an innovative method of setting and controlling the clamping force of electrodes in the resistance welding technology.

The commonly used solutions of the clamping system in resistance welding machines are based on the pneumatic clamping system. This is a conventional system that has advantages, such as relatively low component costs. Here, however, the advantages end, and the disadvantages of using such a solution only appear, namely:

- lack of adequate dynamics of electrode movement,

- excessive noise,

- necessity to use compressed air installation in the production hall,

- impact contact of the electrodes with the welded material at the beginning of the welding process,

- no possibility to control the course of the clamping force during the welding current flow.

These requirements are met by an electromechanical system for controlling the force and/or displacement of electrodes, and an appropriate algorithm for controlling the pressure (force and/or displacement of electrodes). Such innovative control allows to perform repeatable and qualitatively better welded joints. You should be aware that welded joints are part of metal structures (e.g. car body), where failure to comply with the technology (welding) conditions may result in failure of the structure itself, and also poses a threat to health or life.

The effects of our work have been recognized by experts. Some examples below.

1. Inventions, utility and industrial models which have been exhibited at international or national exhibitions or fairs:

- 2014 - A method and device for welding with a servo-mechanical clamp, Poznan International Fair, gold medal;

- 2014 - A method and device for welding with a servo clamp, 110th International Invention Fair CONCOURS - LÉPINE, Paris, silver medal.

2. The Patent Office of the Republic of Poland granted 5 patents for innovative solutions in the field of welding machine construction with SED and innovative methods of controlling the clamping of electrodes: P.234119, P.228089, P.229445; P.226755; P.220870; P.425968.

Who uses the project results?

The project results will benefit:

- manufacturers of resistance welding machines in the first place, because they will use an innovative solution in the construction of the welding machine,

- in the next step, manufacturers who use resistance welding technology in the production cycle, performing the technological process of bonding through welding technologies in a qualitatively better way,

- at the end of the chain of using an innovative solution we are all, ie car users, housewives, all those who use household appliances (washing machines, refrigerators), users of electronic equipment.

What was the greatest challenge during project implementation?

The biggest challenge was to define the boundary parameters that could be achieved - due to the fact that there was no information about similar solutions, both in Poland and abroad. Knowing the technical possibilities, in this case the speed of force setting and control, a completely new area of new possibilities appeared, i.e. new parameters of the technology. So far, no one has made (because they have not been able to make) welded joints for the force setting parameters proposed by the authors of the project.

Our advice for other applicants

To do a lot, you need to take the first step.