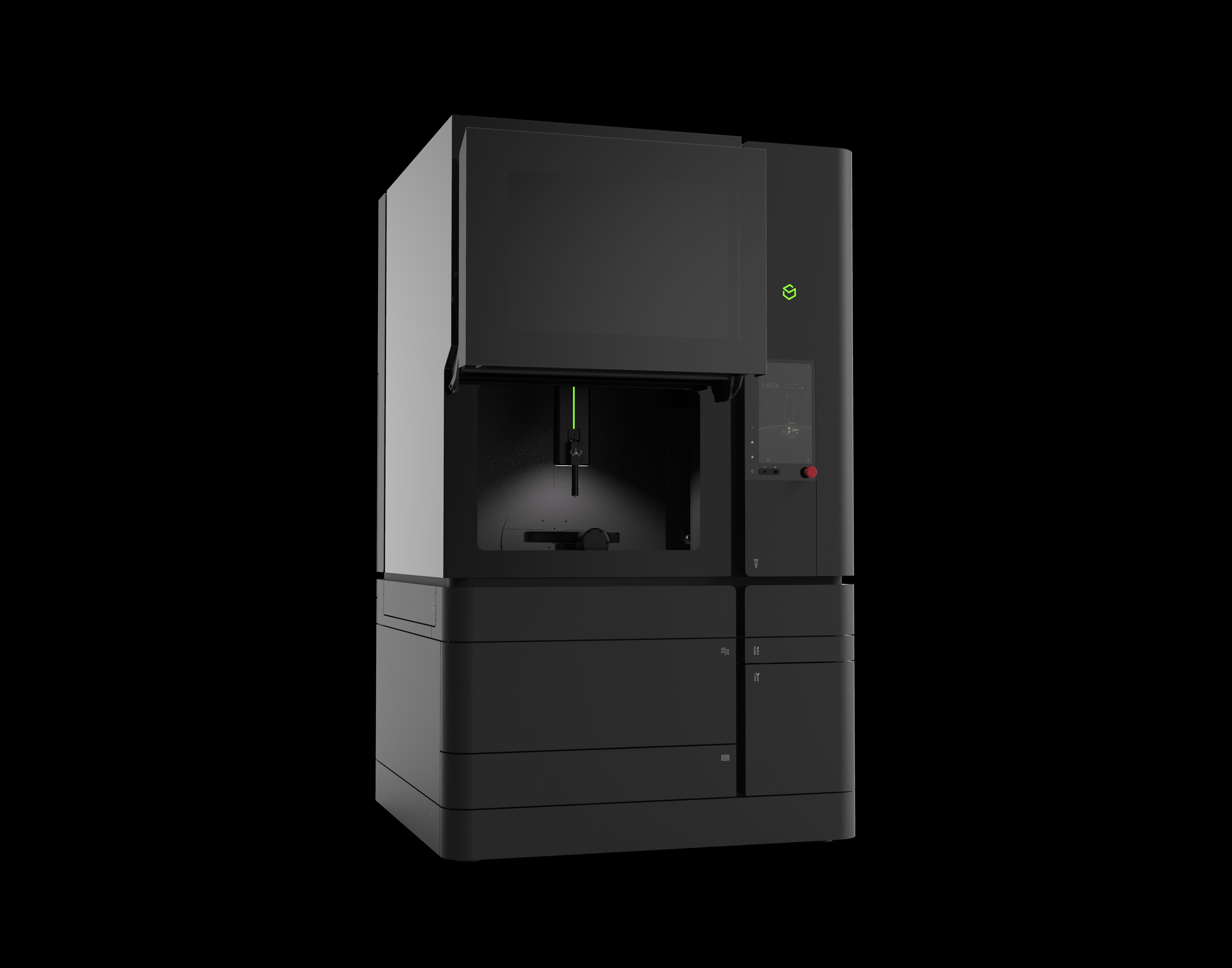

An innovative on a global scale 3D printer

The development of VSHAPER 5AX technology has introduced to the world of 3D printing the previously unheard-of solutions

Project title

Project title

An innovative on a global scale 3D printer

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Vshaper Sp. z o.o. (limited liability company)

Name of programme

Name of programme

Intelligent Development Operational Programme

Competition

Competition

Fast Path

Project value

Project value

PLN 11 904 240.80

Funding value

Funding value

PLN 8 582 632.92

Project delivery period

Project delivery period

from 1 February 2016 till 30 November 2019

Meet our team

The design team consisted of almost 20 people. Designers, graphic designers, programmers, electronics engineers, constructors, fitters and managers collaborated on the creation of the VSHAPER 5AX MACHINE project. We all did our best to achieve the common goal - we have created a machine that is already generating astonishment in the world and is highly desirable.

View the results of our work

What problem is addressed by the project?

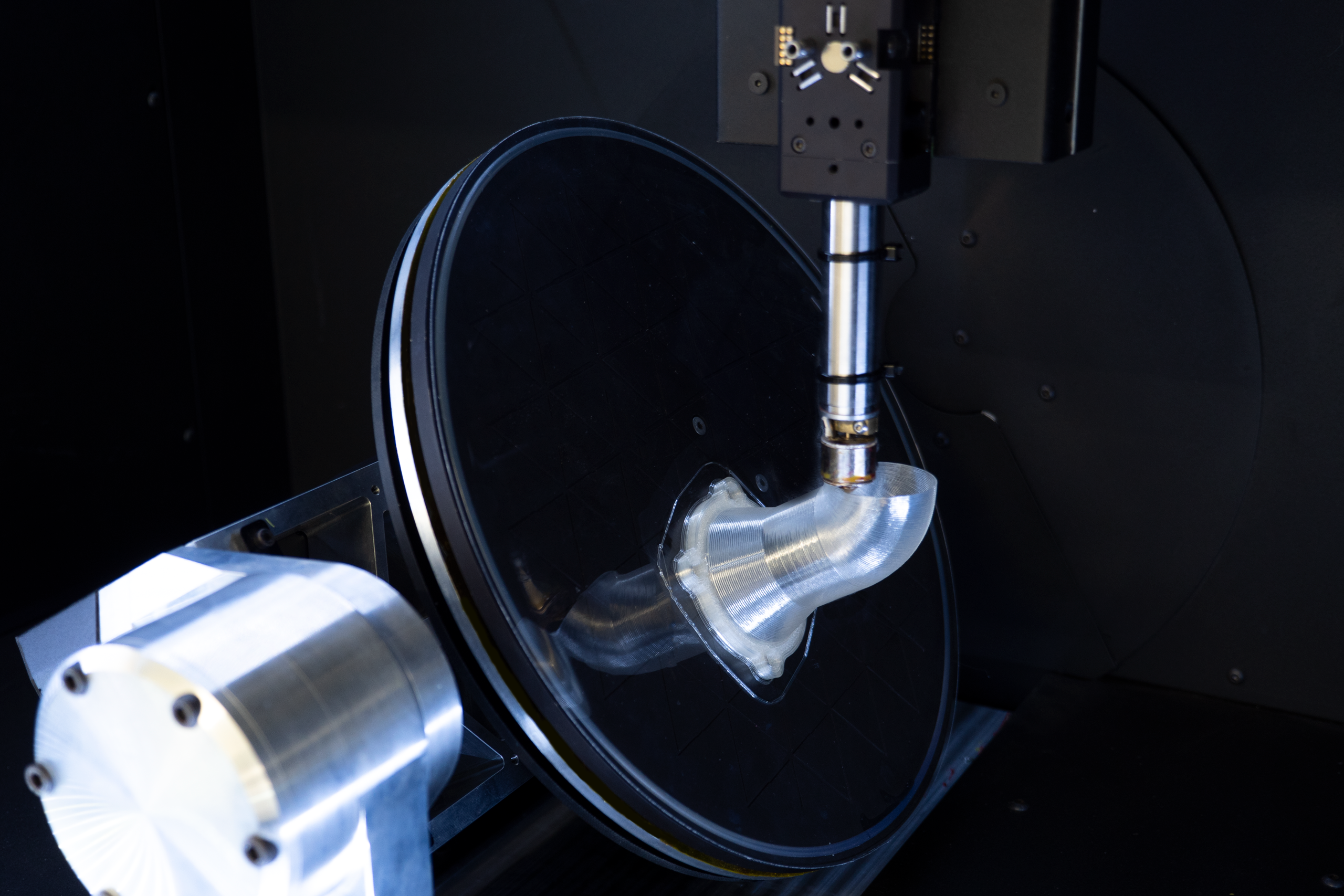

The development of VSHAPER 5AX technology has introduced to the world of 3D printing the previously unheard-of solutions. The innovative 5AX printing solutions enable the printing of complex models that require the transfer of heavy loads in various directions and joining various materials. The 5AX technology optimizes production processes, allows for more advanced personalisation of a product and significantly reduces the time of putting it on market in mass production. This machine can therefore be used for prototyping models with a high degree of complexity, but also solves the problem of the production of highly complex elements made in small amounts. Thanks to an assumed wide range of materials, these models can be used in a wide range of industries. The possibility of printing with materials of high temperature, chemical and mechanical resistance means that the models printed with VSHAPER 5AX MACHINE can be used even for the toughest industrial applications. In addition, the use of 3D printing allows you to achieve savings of up to 70% compared to subtractive manufacturing. It is also much more ecological due to, among others, a much lower production of waste, which in this case is generated in minimal amounts. Time is also a very important factor. It usually takes a few to a dozen or so hours from the design of the model to the physical object that meets all the assumptions! It can therefore be assumed that the introduction of the VSHAPER 5AX MACHINE to the market has compiled solutions to the problems posed by traditional - three-axis - 3D printers and a number of new - much more advanced ones.

We would like to cordially invite you to familiarize yourself with the project on our website: https://vshaper.com

Who uses the project results?

The VSHAPER 5AX MACHINE project and its effect in the form of a 5-axis 3D printer were from the very beginning addressed to companies with an identified need to create complex models, that could not be met by conventional 3D printers. Thanks to the use of many innovative and proprietary solutions, such as a rotary-tilt work platform, a sub-pressure and heated worktable, a closed and actively heated work chamber - VSHAPER 5AX MACHINE is able to meet the requirements ensuring highest quality and precision of the models created.

What was the greatest challenge during project implementation?

The biggest challenge during the project implementation was to adapt VSHAPER 5AX to the maximum optimization of work. In addition to the fact that we have created a machine with unprecedented solutions - we also wanted to ensure that it can be used as comfortably as possible. This was achieved thanks to a thorough analysis of the needs and the introduction of amenities such as: a large, easy-to-read panel for operating the machine, a filament box that allows you to store and change the material used directly in the printer. In addition, the possibility of conducting precise measurements using a special head has been introduced as well as milling directly in the machine, for which a special head has also been provided. There is also an automatic calibration function. These and many other solutions reduce the workload associated with the operation of the machine, which allows you to optimize its work as much as possible.