Demonstration of an authorial technology for the production of A.S.SET components and composite parts

As part of the project, a technology for the production of both semi-finished products for the production of composites and ready-made composite elements was developed

Project title

Project title

Demonstration of an authorial technology for the production of A.S.SET components and composite parts

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

New Era Materials Sp z o.o. (limited liability company)

Name of programme

Name of programme

Intelligent Development Operational Programme

Competition

Competition

Demonstrator

Project value

Project value

PLN 32 904 415.36

Funding value

Funding value

PLN 13 161 766.14

Project delivery period

Project delivery period

from 1 March 2016 till 30 September 2019

View the results of our work

Examples of the implementation of project’s results

What problem is addressed by the project?

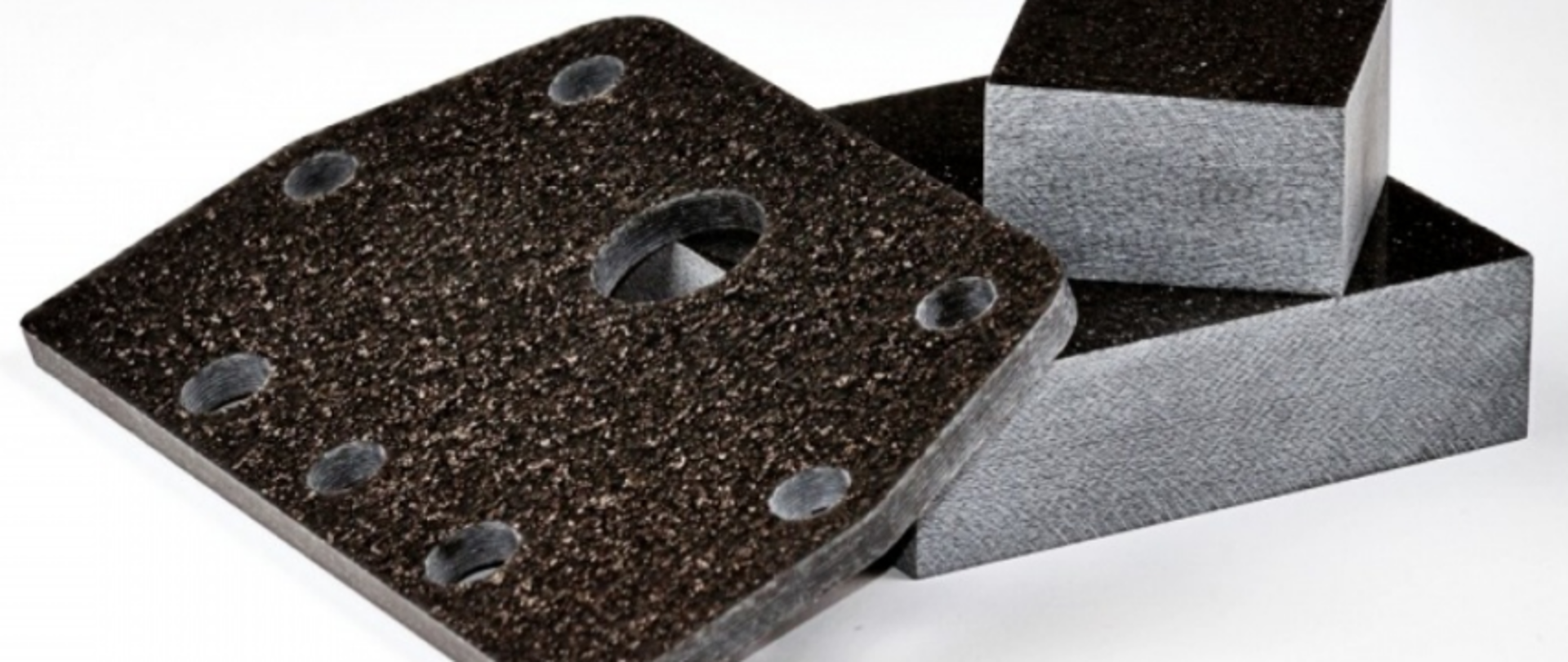

As part of the project, a technology for the production of both semi-finished products for the production of composites and ready-made composite elements was developed. A one-component epoxy resin was used, which is the company's proprietary solution. The developed technology resulted in the achievement of measurable technological benefits (e.g. no need to prepare components for the process), as well as material (e.g. extending the lifetime of a single-component resin in a non-crosslinked state) and economic advantages (e.g. shortening the production cycle). in terms of competitiveness the greatest advantage of the developed solution can be the possibility of using components that cannot be used in production based on alternative technologies. Thanks to the use of a single-component epoxy resin in the form of a powder and the pouring technique, it is possible to use components with a higher melting point than the process temperature. Based on this idea, the Company has developed a range of solutions, including fire retardant resins. The developed NEMpreg fire retardant meets the highest requirements of the PN-EN 45545 standard.

The presented material is also competitive from an economic point of view. The use of the developed mixture of fire retardants in a solid form allowed to achieve the required parameters at a much lower cost in comparison to market products. This aspect significantly contributed to the popularisation of the project's results.

Who uses the project results?

The development of a range of solutions in the area of composite materials enabled a significant development of the Company in selected areas of industry:

- Railway industry - the development and implementation of the NEMpreg fire retardant product allowed to achieve the highest class of fire retardancy for the railway industry. However, the use of modern composite solutions not only increases the safety of train passengers, but also, by reducing the weight of the whole train, leads to measurable economic gains (lower fuel consumption).

- Transport - high stiffness, low weight and resistance to weather conditions enabled the effective use of the material solution developed as part of the project material solution for the production of sandwich-type composites, which are successfully used in the production of wheelchair platforms for buses.

What was the greatest challenge during project implementation?

The biggest challenge was the need to develop a new demonstration line for the production of plasticized resin infiltrated prepregs. Before starting the project, we focused on powder resins, but during the course of the project it became necessary to develop new formulations that could only be applied in a plasticized form.

Our advice for other applicants

Select projects for implementation that genuinely fit into the company's long-term plans.

Do not be afraid to introduce changes during the project implementation if the results of the works carried out indicate the need for change.

It is absolutely necessary to keep order in the documentation.

Staff quality and commitment are of critical importance.