InnerWeb

InnerWeb – a system for the administration and monitoring of e-permits in industrial plants

Project title

Project title

InnerWeb – a system for the administration and monitoring of e-permits in industrial plants

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

InnerWeb Sp. z o.o.

Name of programme

Name of programme

Smart Growth Operational Programme

Competition

Competition

BRIdge Alfa Programme, within the VC Link Fund investment (under competition_ 1/1.3.1/2017)

Project value

Project value

PLN 1,030,000.00

Funding value

Funding value

PLN 824,000.00

Project delivery period

Project delivery period

From 26 February 2021 to 31 March 2022

Meet our team

View the results of our work

We have a global innovation – an in-plant geolocation-based IT system. InnerWeb® brings Progress to work organisation, including in cooperation with external companies.

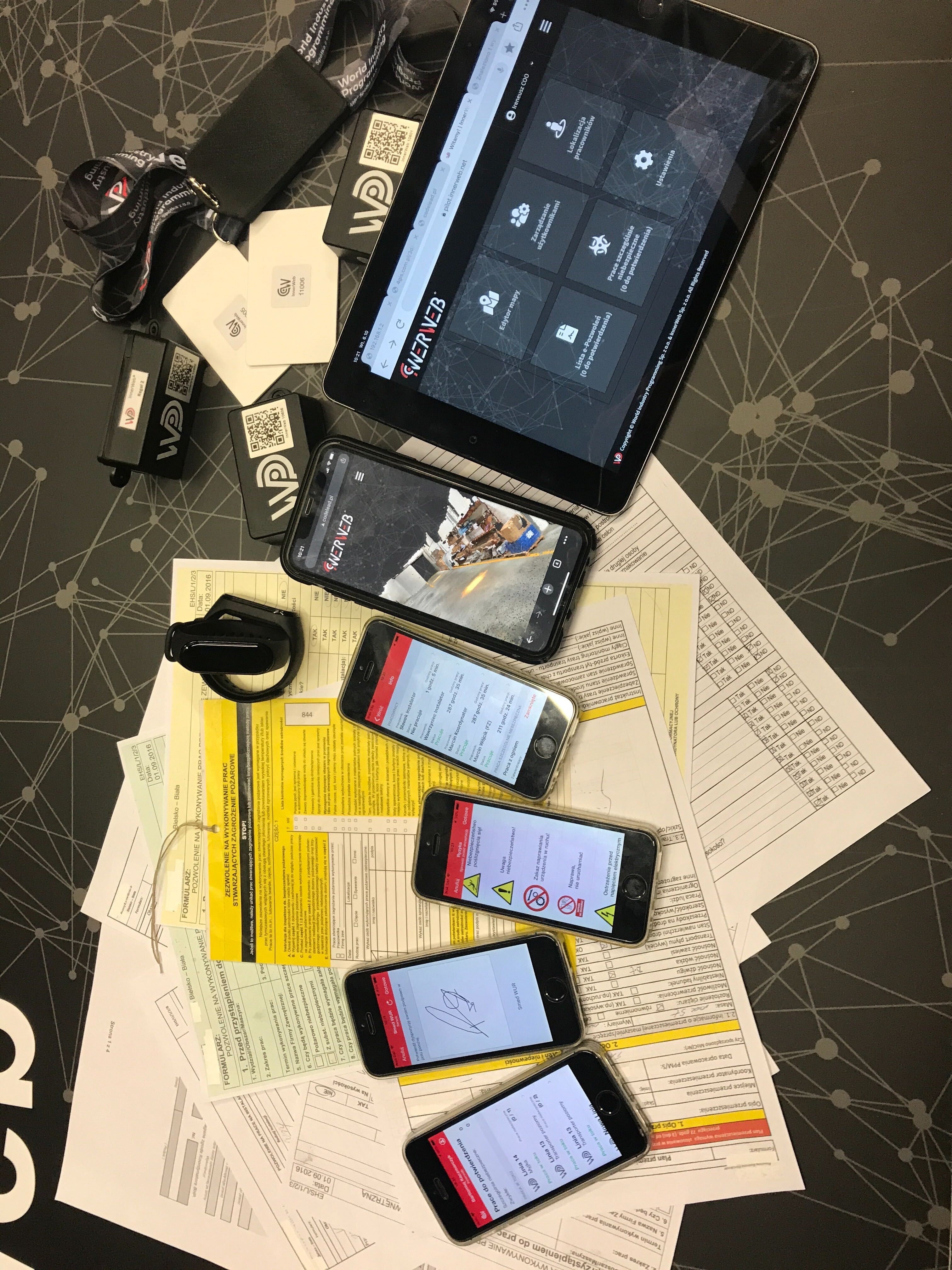

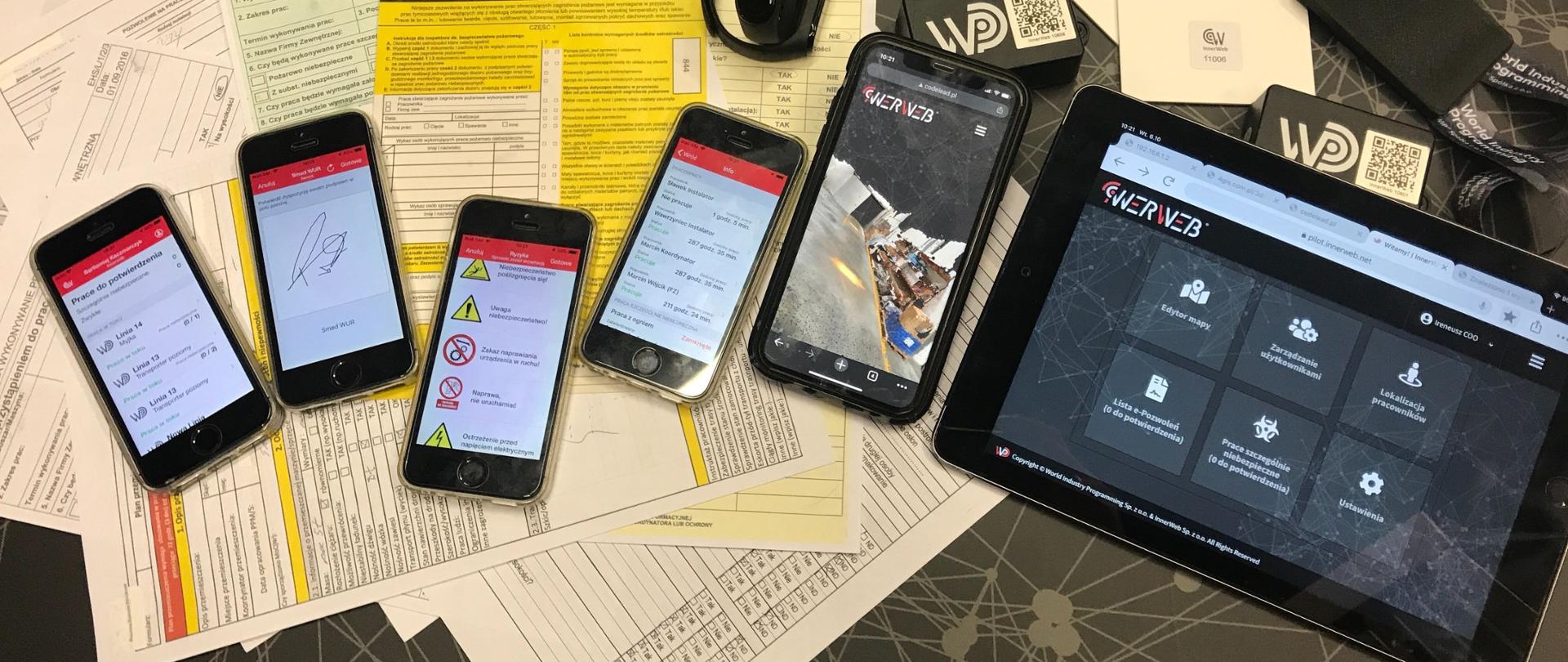

In a matter of several weeks, without stopping the production process, we transform your plant into a Plant 4.0. With our radio beacons relying on Bluetooth, each machine/location on the shop floor has its own operational history, access to documents (manuals, schemes, pictures), a list of work-related hazards and the required personal protective equipment, as well as a list of periodic work that needs to be done in a given location. InnerWeb® is based on built-in work e-Permits with biometric signatures, allowing each employee to issue a work permit in a matter of seconds to perform machine maintenance, repairs and upgrades on the shop floor. InnerWeb® verifies the working location of the trained staff and confirms that the employees are present in their respective work sites. Our solution also checks the validity of authorisations to perform high-risk work. The highlight of the InnerWeb® system is the PRE-fire protection, sounding alarm when the employees leave the location of fire-related work unattended. InnerWeb® monitors the “living tissue” of the plant – i.e. employees, as well as tools and peripheral devices that are in operation. InnerWeb® is a powerful tool in the hands of engineers and experts in an industrial environment. Routine activities which until recently took from several do several-dozen minutes can now be performed in a matter of a couple of, or a dozen, seconds.

And this boost in productivity, coupled with increased employee and plant safety, is the most valuable output delivered by the InnerWeb Team.

What problem is addressed by the project?

Our main goal was to reduce the time needed to prepare work permits. In most large plants across the world, this process takes from 30 minutes to even an hour. With our automation solutions, this time could be reduced by 92%.

Through automation, we were able to solve the problem of in-plant employee work permits. InnerWeb® makes sure that employees have valid authorisations to perform work. Moreover, our automation-based solutions helped to address ongoing workplace supervision. The PRE-fire protection is integrated with InnerWeb® and can be used in hollows and workplaces in which employees need to secure each other. With the geolocation system, we could solve the problem of not knowing where and by whom a given work is being currently performed within the plant. Moreover, we addressed the issue of finding machine documentation, schemes and other necessary documents. Now, employees can access them while working at the machine. Geolocation also helps to monitor the location of specific tools and peripheral devices, such as injection moulds, thermoregulators, flow metres, platforms, ladders, specialised equipment, etc. InnerWeb® makes it much easier to find them. Furthermore, with attendance checking, plant managers can monitor external contractors’ working time, helping them to supervise and verify the scope of contracted work. And this also addresses the problem of compiling and reviewing lists of emergency and urgent work contracted without bidding. Another issue solved by InnerWeb® is the time-consuming process of reporting failures, purchasing needs, ideas and tasks. It shortened this process to several seconds, and introduced the add-picture option to make it clear what is being reported.

One other interesting application of InnerWeb® involves the monitoring of employee evacuation and automated employee counting. This includes an option to monitor employees who work alone for signs of inactivity, especially during afternoon and night shifts, and on days off.

Who uses the project results?

Originally, InnerWeb® was addressed to large manufacturing plants and industrial groups with a workforce of several hundred to several thousand employees. It is easy to measure the benefits for such establishments. However, our solution is now attractive for medium-sized enterprises as well.

Once work is completed on Evolutionary Algorithms, which are responsible for the location accuracy within the iBeacon (BLE) radio beacon network in the plant, the resulting computational module will be applicable in other sectors of the economy, including public buildings (bus or train stations, airports, shopping malls, museums, etc.). Our research aims to achieve a geolocation accuracy of less than 1 m.

InnerWeb® will benefit mainly people – employees in industrial plants, engineers and other professionals. It is them who each day perform repetitive, monotonous activities which are of little productive value and yet consume valuable time. Technology should support people and provide a cheaper alternative to outdated procedures.

What was the greatest challenge during project implementation?

The first challenge was to understand and study in depth how the signal from the BLE radio beacon behaves both physically and in terms of its management through mobile apps. There are few publications which address this problem. We had to do the bulk of the work on our own, building and consolidating our know-how.

Another challenge involved finding the way to present real-time employee and object traffic not only from the simplified top-down perspective, but also in such a manner as to accommodate existing technology. To this end, we used the LIDAR solutions integrated in the latest mobile devices to scan internal spaces and manufacturing lies. With this technology, we can make a virtual reproduction of the entire plant and feed it with data from InnerWeb®. This involved the difficulty of creating a platform that aggregates point clouds and connects them into a single cloud with a very high accuracy.

Our advice for other applicants

What you should know is that by deciding to look for support for your project, you are already halfway to success. And it will take you many months of work, and a lot of application and schedule writing and talking to get there. Be persistent – the best entrepreneurs have this quality. You need to try, even a couple of times – it is a part of the process. Remember that it will take time either way. If our idea is recognised or awarded in a competition by the top experts in Poland, NCBR will help you gain clarity and position you to grow further internationally. Good luck!