Interdisciplinary Environmental Doctoral Studies in “Physical, Chemical and Biophysical Foundations of Modern Technologies and Materials Engineering” (FCB)

Project title

Project title

Interdisciplinary Environmental Doctoral Studies in “Physical, Chemical and Biophysical Foundations of Modern Technologies and Materials Engineering” (FCB)

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Faculty of Physics and Applied Computer Science, AGH University of Science and Technology, Krakow

Name of programme

Name of programme

“Knowledge, Education, Development” Operational Program

Competition

Competition

Interdisciplinary Doctoral Study Programs – Interdisciplinary Environmental Doctoral Studies in “Physical, Chemical and Biophysical Foundations of Modern Technologies and Materials Engineering” (FCB)

Project value

Project value

PLN 10,123,883 for 75 beneficiaries

Funding value

Funding value

PLN 134,895 per postgraduate student

Project delivery period

Project delivery period

01/09/2017 – 31/08/2022 (extended to 31/10/2023)

See the effect of our work

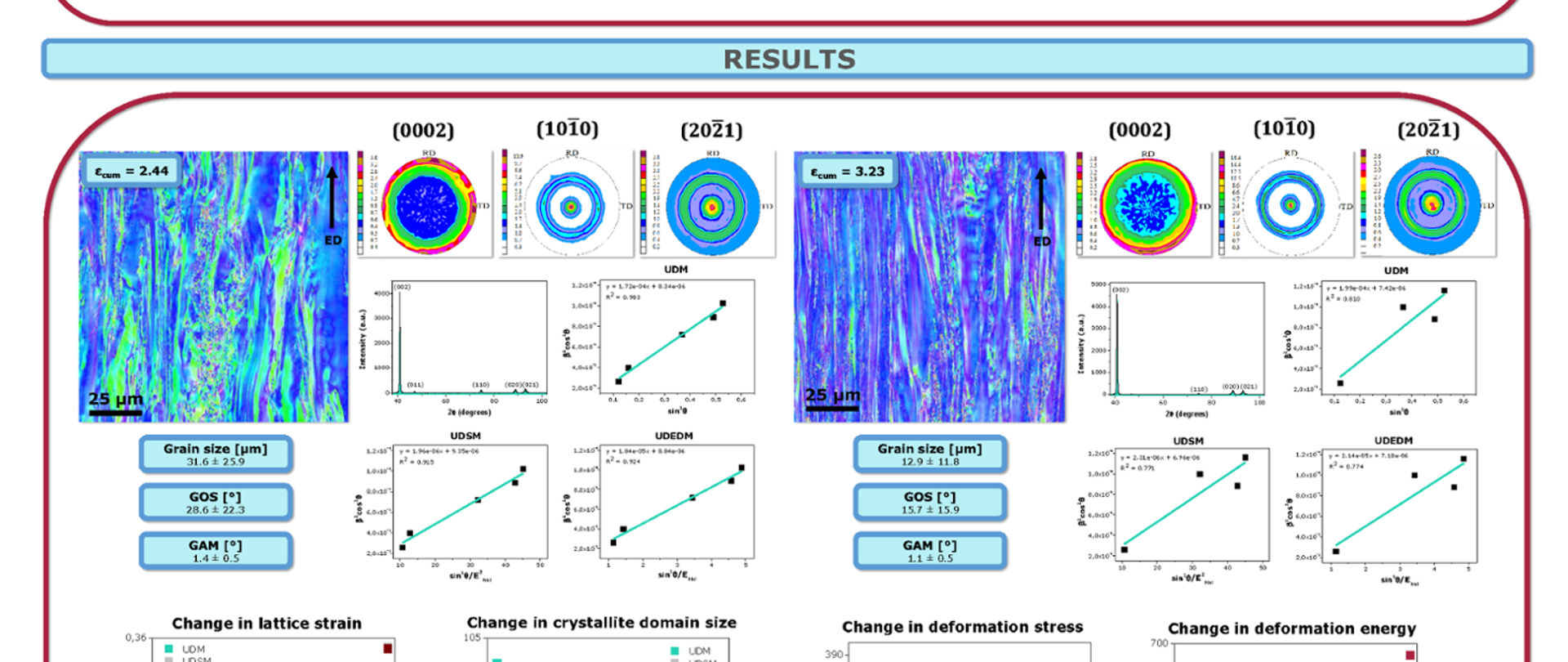

The work concerned the search for sources of improvement of mechanical and biophysical properties of pure titanium obtained by an unconventional method of plastic deformation. The most significant and original result of the work was the discovery of factors influencing the dynamic cellular response occurring on the surface of hydrostatically extruded titanium. In addition, in-depth characterization of the parameters causing an increase in the strength of the material was made. During the research, a detailed analysis of changes in the microstructure of titanium during the hydrostatic extrusion process and the significance of low-temperature annealing on the mechanical properties and microstructure of titanium was also carried out. As a result, 4 scientific articles were written, expanding the current state of knowledge in the field of plastic deformation of titanium, as well as its biophysical and mechanical properties.

Publications

What problem does our project solve?

The interest observed in recent years in ultra-fine-grained materials, obtained by means of intensive plastic deformation techniques, the so-called SPED methods, is dictated by the need to miniaturize objects and improve their properties. Biomaterials obtained by SPED methods are characterized by increased mechanical strength, corrosion resistance and biocompatibility, and therefore a set of key features from the point of view of potential biomedical applications. It is widely believed that the fragmentation of the microstructure determines the strength of the material, but the question of the genesis of the modified improved biophysical properties remains unclear. The main objective of the study was to determine the factors affecting the improvement of mechanical and biophysical properties of pure titanium subjected to the hydrostatic extrusion process.

The research has shown that the mechanical properties of the material are largely determined by a strong substructure and a huge share of large angle boundaries. Thanks to the hydrostatic extrusion process, it is possible to almost double the strength of pure titanium in comparison with coarse-grained non-deformed material. Titanium obtained by hydrostatic extrusion is characterized by anisotropy of biophysical properties. Regardless of the analyzed cell line or protein solution, small grain size, hydrophilicity, surface roughness or its chemical composition do not have a decisive influence on the cellular response of the material. The presence of surface defects and prismatic planes seems to be crucial for the proper development of cells on the surface of the SPED-treated material. Hydrostatically squeezed titanium can be used in dentistry and orthopedics due to the intensity of cellular processes occurring on its surface with the participation of osteoblasts.

Who will benefit from the results of the project?

Project results significantly expand the current state of knowledge regarding plastic deformation of titanium, hydrostatically extruded materials and metallic biomaterials in the context of their biocompatibility. The positive influence of grain crystallographic orientation on the cellular response of the material paves the way for the design and manufacture of modern materials for biomedical applications. The results of the project will benefit material engineers and biotechnologists dealing with phenomena occurring at the material/cell interface. In addition, the results of the project may be helpful in the production of unconventional titanium-based materials with high mechanical strength. Project data indicate a positive effect of low-temperature annealing on the plasticity of high-strength titanium, and therefore project results could be relevant for metallurgical specialists, including those concerned with materials forming and heat treatment technologies.