INVITES

INVITES innovative devices for intensified CO2 removal from waste gases

Project title

Project title

INVITES innovative devices for intensified CO2 removal from waste gases

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Łódź University of Technology and OMNIKON Sp z o. o.

Name of programme

Name of programme

International programmes

Competition

Competition

The project was carried out as part of the second STAIR competition in the Polish-German cooperation for sustainable development, co-financed by the National Centre for Research and Development and the Federal Ministry of Education and Research.

Project value

Project value

PLN 1,426,358.00

Project partners

Project partners

PLN 35,113,760.33

Project delivery period

Project delivery period

ENVIMAC GmbH, Niemcy, OMNIKON Sp. z o.o.

View the results of our work

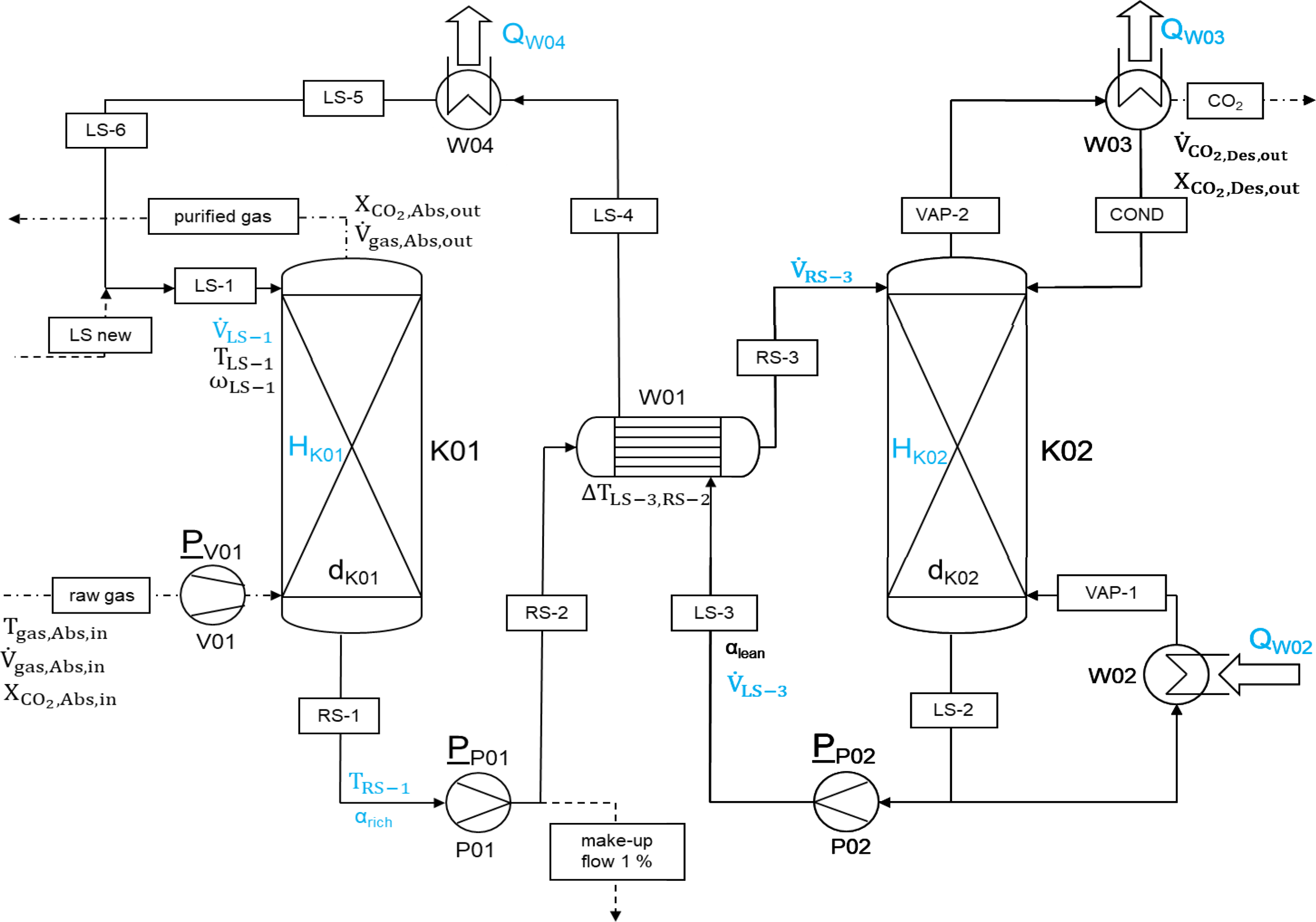

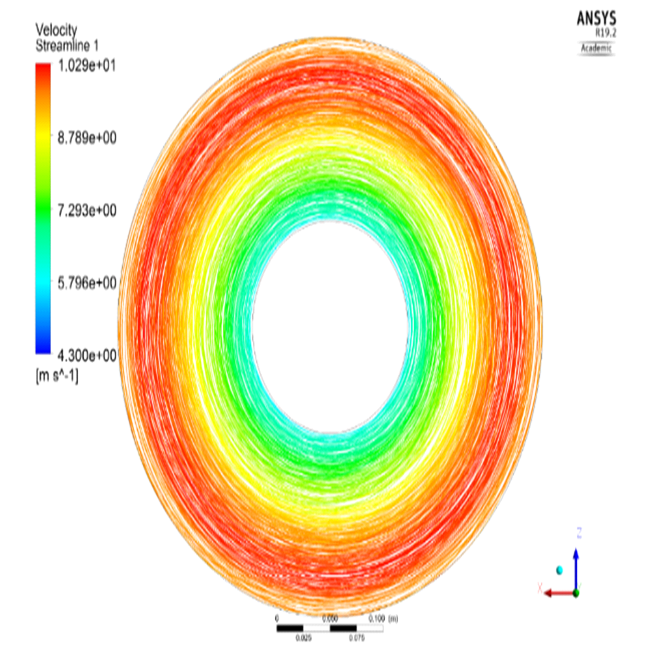

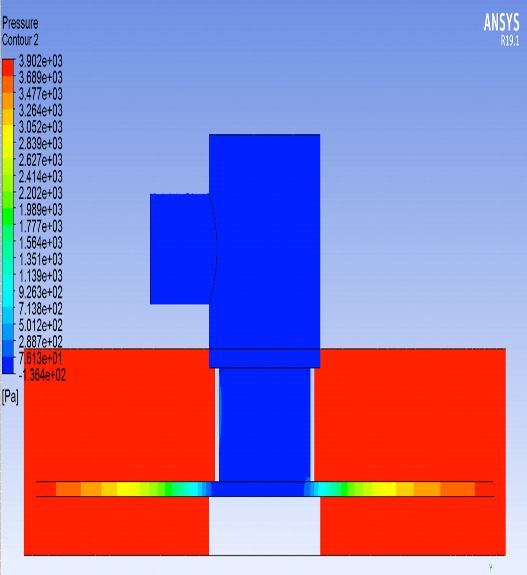

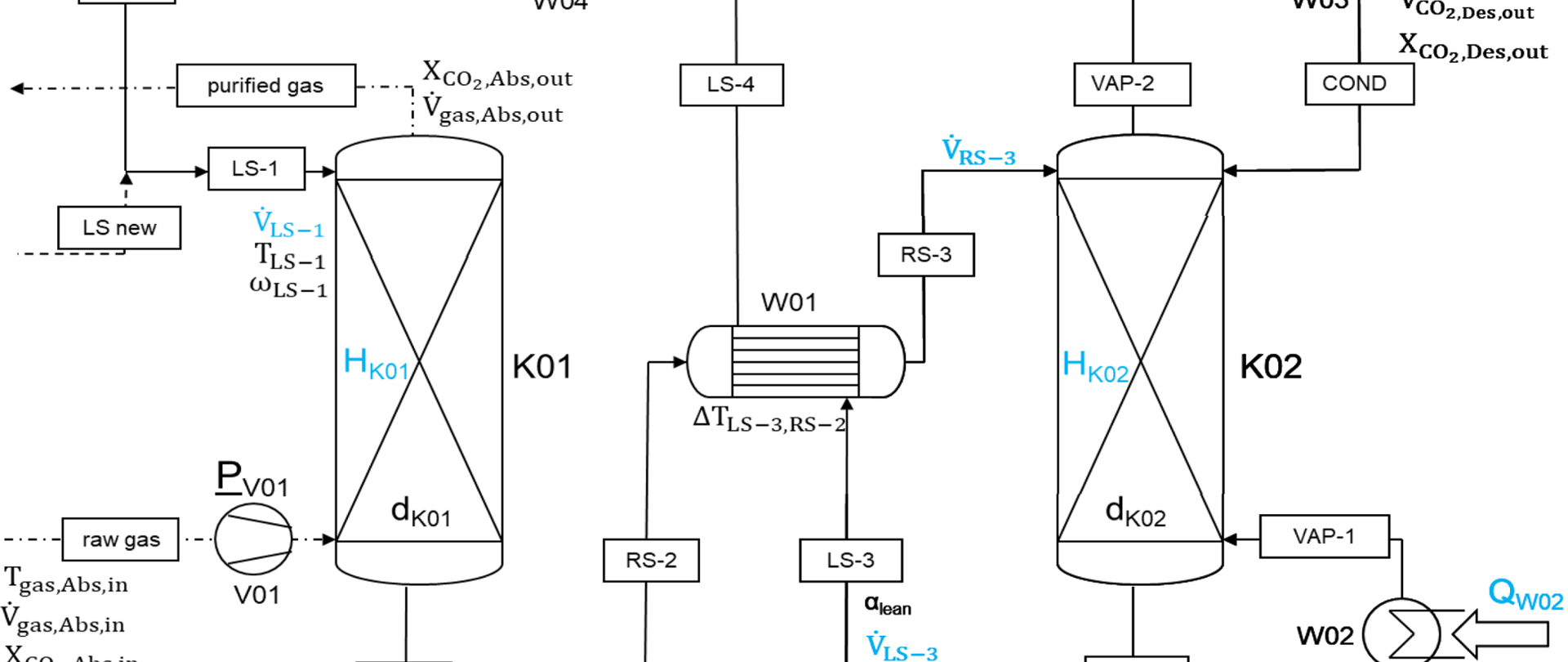

Velocity and pressure distributions obtained from numerical computations (CFD)

The technical/technological outcome of our work was the construction (together with the project’s Polish partner – Omikon Sp. z o.o.) of a unique research system which allows research into, and the optimisation of, gas absorption processes in a device with a rotating packed bed, in relation to process parameters used in industrial installations. Research outcomes include primarily:

- Proposed and validated methodology allowing empirical comparisons between the parameters of conventional absorption towers (produced by Envimac GmbH) and absorbers with rotating packed beds, researched at the Łódź University of Technology.

- verified mathematical models through experimental tests and computer simulations (CFD).

- Based on ISO 14040-14044 Standards, we conducted LCAs to gain insights into the environmental impact of two gas absorption technologies, i.e. in tower apparatus and using rotating absorbers.

Business outcomes include primarily the know-how, the commercialisation of which is and will be the subject of business negotiations aimed at deploying the RPB technology in chemical companies and the broadly defined energy industry.

Have you managed to develop a market-ready product or technology?

While RPB absorbers have exceeded the technological maturity threshold required by industry, they continue to be seen as “a novelty”, and there have been few commercial applications of them. And this is in spite of the benefits deriving from RPB as an alternative to filled towers, including:

- economic: lower capital expenditures, lower operating costs.

- process-related: higher efficiency, easier scalability and process universality of the devices.

- environmental: primarily by reducing emissions to the atmosphere.

- safety: through smaller volumes (up to 30 times) of the devices.

This shows that RPB absorbers are used primarily in industrial processes involving the absorption of environmentally harmful gases (NOx, SOx, H2S, CO2, acetone, ammonia, butadiene, benzene, chlorides, etc.) and the absorption of valuable components in gas mixtures.

What was the pathway to the commercialisation of results?

The above-mentioned potential areas of RPB technology’s application were a catalyst for the talks between the INVITES Project Consortium and representatives of chemical and energy companies. Our current discussions focus on finding an area in which RPB absorbers could be deployed in existing process lines with minimal time and resources, e.g. as a bypass of existing towers or reactors.

Have you encountered difficulties with the commercialisation and if so, how did you manage to overcome them?

Deploying a new technology in an industrial environment is a time-consuming process (especially at plants which operate flammable/explosive streams), as it requires extensive performance tests and compliance with all the strict safety standards. Realistically, we should expect first industrial deployments in Poland within 3÷5 years, while it will take 5÷10 years for RPB technology to become common, i.e. after long-term testing in an industrial environment (explosive media, dusting, vibration, etc.).

How was the issue of intellectual property in the project resolved?

The scope of intellectual property contributed by each project partner and the rules of using the know-how obtained through INVITES project implementation are set out in two consortium agreements – one Polish (Łódź University of Technology – Omnikon) and one international (Envimac – Łódź University of Technology – Omnikon).