Multifunctional polymeric membranes modified using hybrid surface engineering technologies

Project title

Project title

Multifunctional polymeric membranes modified using hybrid surface engineering technologies

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Łukasiewicz Research Network – Institute of Exploitation Technology

Name of programme

Name of programme

National programmes

Competition

Competition

LEADER VII

Project value

Project value

PLN 688,000.00

Funding value

Funding value

PLN 688,000.00

Project delivery period

Project delivery period

from 01.01.2017 to 31.12.2020

Meet our team

Project Manager – Eng. Joanna Kacprzyńska-Gołacka, PhD

MSc Wioletta Barszcz

Eng. Anna Kowalik-Klimczak, PhD

Eng. Monika Łożyńska, PhD

MSc Paulina Rajewska, PhD

MSc Jarosław Skowroński, PhD

Ewa Woskowicz, MA

Eng. Piotr Wiecinski

See the result of our work

What problem does our project solve?

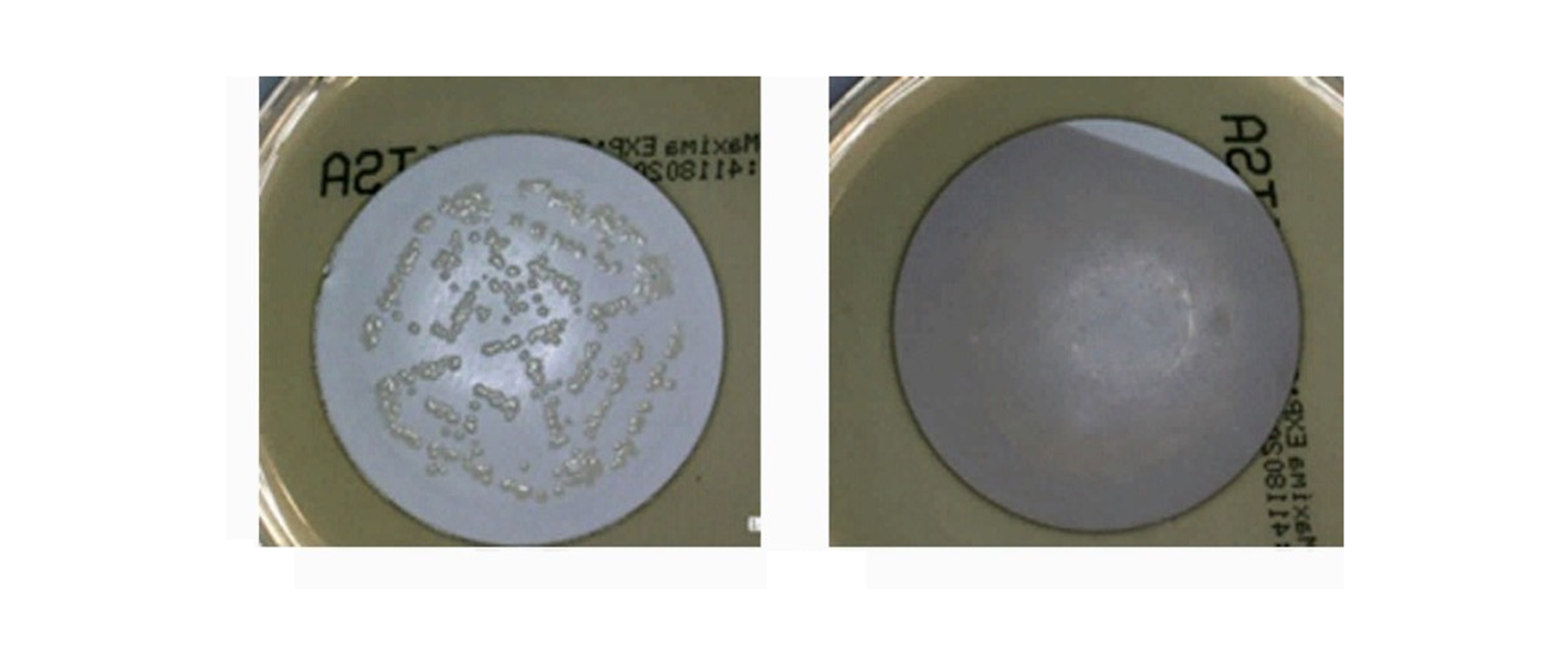

Polymeric microfiltration membranes are widely used in wastewater filtration processes in the dairy industry and enable the introduction of a closed-loop economy in this area. At present, the main limitation in the use of polymeric membranes in filtration processes is the phenomenon of biofouling, which is the colonisation of membrane surfaces and pores by micro-organisms. As a result of this phenomenon, there is a significant decrease in the efficiency of the filtration process.

The main objective of the project was to develop a model surface treatment technology to produce a multifunctional membrane with very good hyrdrophilic properties and high bactericidal activity.

The process solutions developed in the project make it possible to modify the functional properties of the filtration membranes, leading to a reduction in biofouling and thus an increase in the efficiency of the filtration process.

The unique properties of the membranes have been achieved using modern plasma surface engineering techniques. The first solution developed involves activation of the polymer surface in a glow discharge plasma. The technology developed enables improved filtration properties by increasing the hydrophilicity of the membrane surface. In addition, the developed non-metallic plasma activation provides an improvement in the chemical reactivity of the membrane, allowing further introduction of elements and compounds to the membrane surface.

The second solution developed is to impart functional properties to the polymer membrane by applying a thin multicomponent coating based on titanium oxide and silver oxide (TiO2+AgO), which, on the one hand, does not block the porous structure of the membrane and thus does not alter its filtration properties, and, on the other hand, makes it possible to impart photocatalytic, hydrophilic and, above all, bactericidal properties.

Who is going to benefit from the project results?

The result of the completed research work is a material and technological solution from the area of surface engineering, providing an improvement in the efficiency of polymeric membranes used in dairy wastewater filtration processes. The developed material solution makes it possible to enrich commercial membrane materials with additional functional properties. The resulting material and technological solutions are of great economic importance for companies using membrane filtration processes. The possibilities for the practical use of the new generation of membranes developed are extensive. By surface-treating existing membranes on the market, we do not change their geometric parameters, which makes them suitable for industrial use in existing filter modules and installations.

Which aspect of the project implementation have we found to be the most challenging?

The biggest challenge was the choice of plasma membrane modification technology and the selection of process parameters. The polymeric materials of which the membranes are made have a low thermal resistance of no more than, 100ºC. In addition, polymeric membranes have a porous structure, which is important in the filtration process and must be retained after the surface treatment stage.

Consequently, there was a high risk of overheating the membrane during the plasma treatment process, which could damage its porous structure and impair or lose its separation properties. Furthermore, the production of metallic coatings by plasma methods at temperatures below 100ºC may have had an adverse effect on the stability and continuity of the deposited coatings and their adhesion to the substrate.

The magnetron sputtering technology chosen in the project enables coatings to be deposited at room temperature, which allowed the membranes to be modified without damaging their structure.