Production operation management system

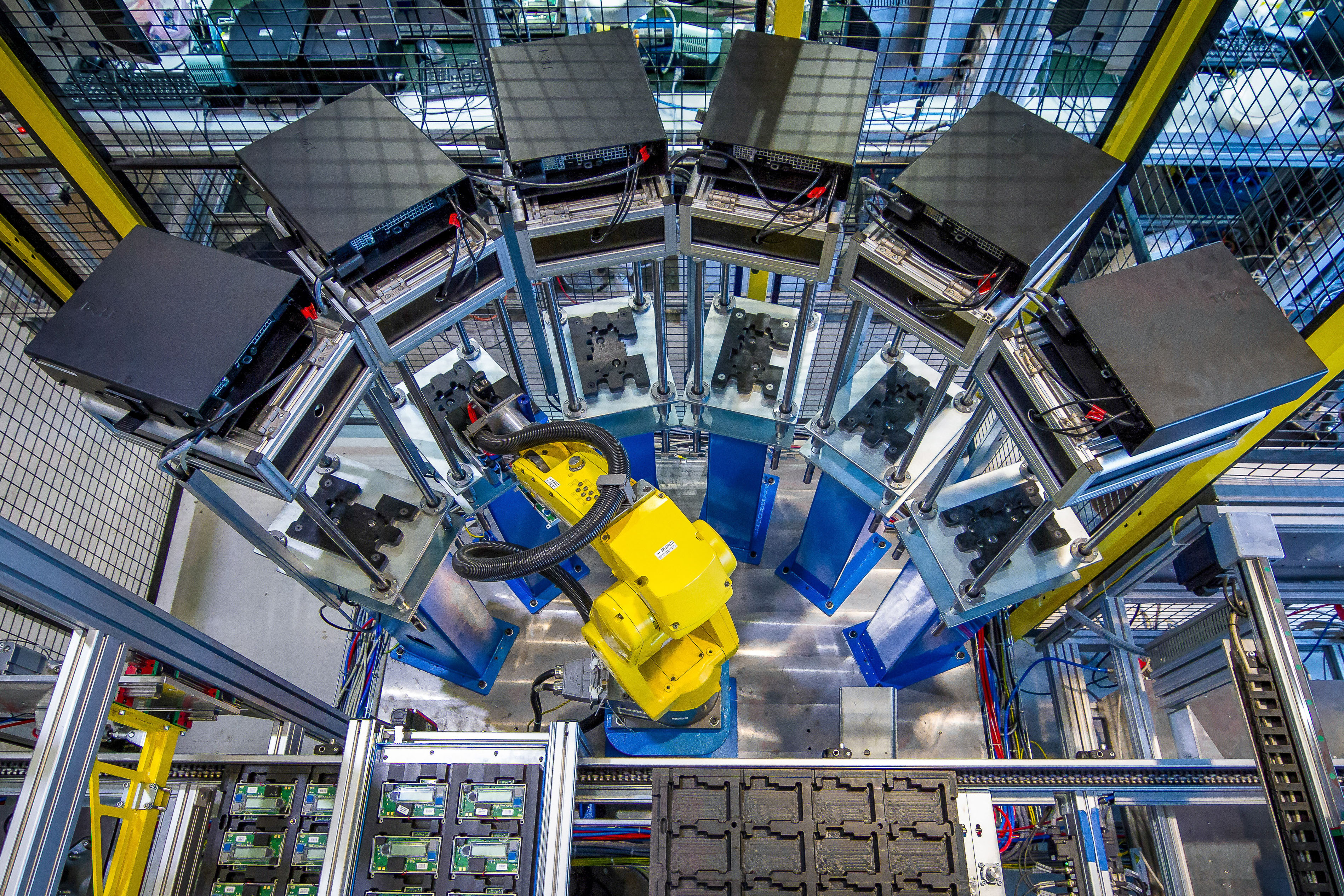

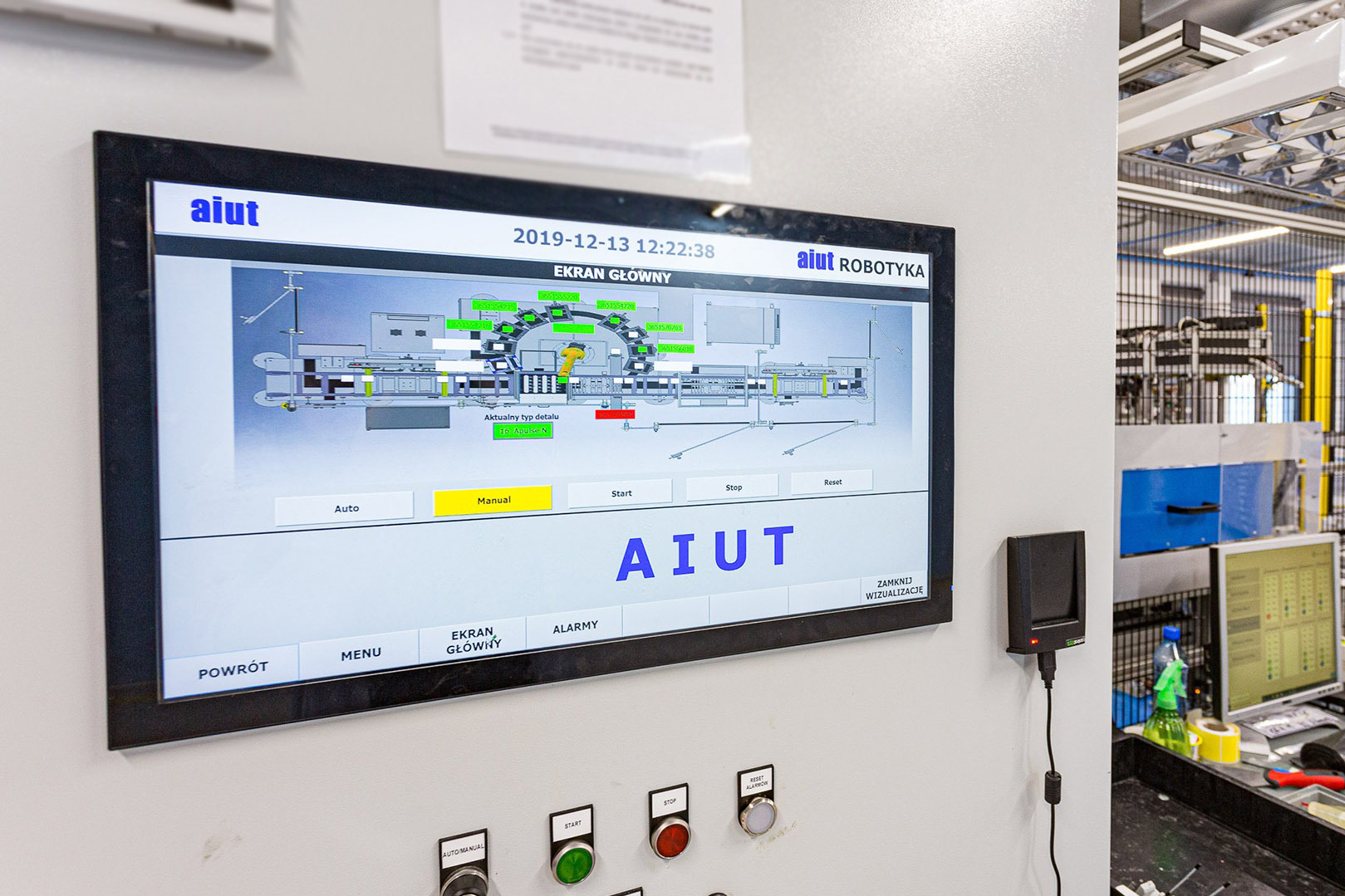

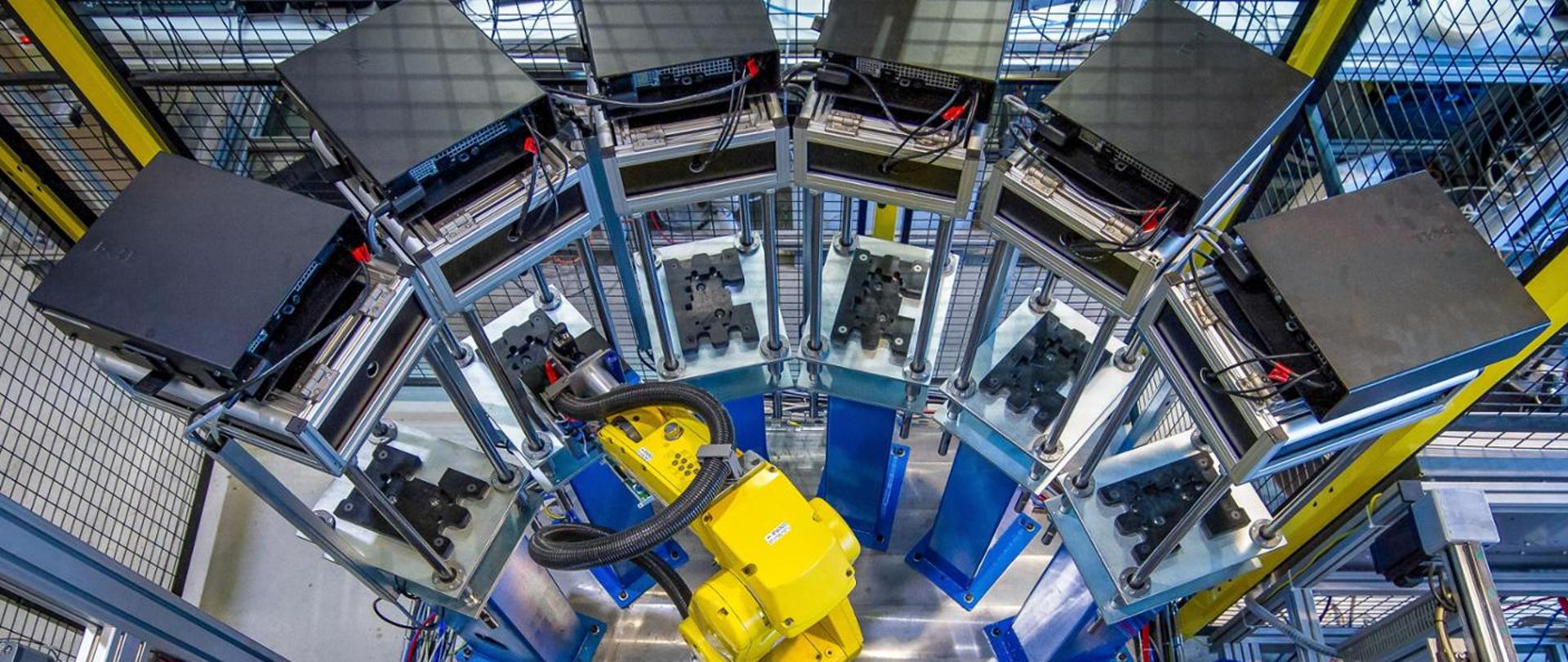

As a result of the project’s implementation, there was created a prototype of a system to support and implement flexible production, which can adapt to changing production environments and multi-variant production with appropriate equipment

Project title

Project title

Production operation management system integrated with knowledge management for preventive and predictive maintenance of production processes in a polymorphic environment

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

Aiut Sp. z o.o. (limited liability company)

Name of programme

Name of programme

Intelligent Development Operational Programme

Competition

Competition

INNOMOTO Sector Programme

Project value

Project value

PLN 5 861 414.11

Funding value

Funding value

PLN 3 750 001.11

Project delivery period

Project delivery period

from 1 June 2017 till 31 May 2020

View the results of our work

What problem is addressed by the project?

As a result of the project’s implementation, there was created a prototype of a system to support and implement flexible production, which can adapt to changing production environments and multi-variant production with appropriate equipment. This solution constitutes a platform for gathering and managing knowledge and organizing the work of the staff running the industrial automation system. The implementation of the system contributes to the improvement of production and increases energy efficiency through the new organization of the production process. Greater efficiency of production has been achieved on several levels: through integrating various types of data necessary for production in a common PFM model, through data management and their exchange between various industrial systems (process automation, production planning and implementation, installation maintenance) to ensure flexible and short-series production, by implementing analytical mechanisms supporting the maintenance of automation installations and increasing knowledge about the process, by launching solutions supporting reactive maintenance of the installation using remote support means and by using knowledge about technology so as to solve problems related to the stability and quality of production.

The key element of the platform is that it provides the staff with unique knowledge and modern means of remote transfer of information and knowledge, including interpersonal communication based on multimedia techniques (such as alternative forms of information transfer - audio / video, VR virtual reality, AR augmented reality).

Who uses the project results?

The system is dedicated to all types of discreet production companies that carry out series and short-series production, in particular in the automotive, tool, furniture, food, transport and lighting systems industries. The solution can be implemented in a complete form or in the form of individual modules, as a production management system, an analytical system supporting efficiency management and production maintenance, and as a remote support system for the maintenance of automation installations. The solutions are dedicated primarily to in-house engineering and production management departments, production maintenance departments as well as logistics and planning departments.

What was the greatest challenge during project implementation?

Undoubtedly, the most critical was the development of a common model for storing, processing and representing data in the target system. This issue known in IT as data integration, required the development of data management methods that would not only reflect all the complex relationships and associations between the components of the process and business, but above all, would be universal enough so as to serve various target implementation environments, and not only for a small group of recipients with a certain specificity of production. Additional challenges were related to the validation of some components, including remote maintenance with the use of VR / AR techniques, due to the recent development of these solutions and the problems associated with them, due to the need to extend research over time, resulting from the study of analytical algorithms over long observation periods, and production management due to the difficulty and specificity of flexible and multi-variant production.

Our advice for other applicants

We advise you not to be afraid of trying to solve non-trivial problems known in the industry. The Polish production market, although characterized by a fairly high level of reproduction and a rather low level of implementation of breakthrough and innovative solutions, is nevertheless a very buoyant, absorbent and dynamically developing market. For this reason, there is always an interest in solutions that improve the efficiency or productivity of the production processes, regardless of whether they are developed in the form of software, hardware or technology. In addition, practice shows the tendency among recipients to gradually implement important solutions, so it is worth developing innovative solutions in a modular form, enabling the launch of a small group of functionalities, which can be gradually expanded with new components. Finally, so as to increase the importance of Poland as a centre of new technologies, it is necessary to constantly conduct research and development, and thanks to the financial support of the National Centre for Research and Development, these processes are significantly facilitated - so it is worth applying and taking up new projects.