The method of immediate additive manufacturing of spare parts and alternative medical equipment

The use of additive manufacturing in various industries enables the creation of virtual warehouses, where it is possible to store data on finished products intended for production and, if there is a demand for a particular detail, its virtual model along with information on manufacturing and its use is transferred directly to the contractor

Project title

Project title

The method of immediate additive manufacturing of spare parts and alternative medical equipment as well as personal protective equipment in a dispersed environment in crisis situations - Virtual AM Storage Covid-19

Name of Beneficiary/Beneficiaries

Name of Beneficiary/Beneficiaries

- Wrocław University of Technology, Faculty of Mechanical Engineering

- J. Gromkowski Provincial Specialist Hospital

Name of programme

Name of programme

National Programmes

Competition

Competition

Support for single-named hospitals in the fight against the spread of SARS-CoV-2 virus infection and in the treatment for COVID-19 patients

Project value

Project value

PLN 2 172 500.00

Funding value

Funding value

PLN 2 079 350.00

Project delivery period

Project delivery period

from 1 July 2020 till 30 June 2021

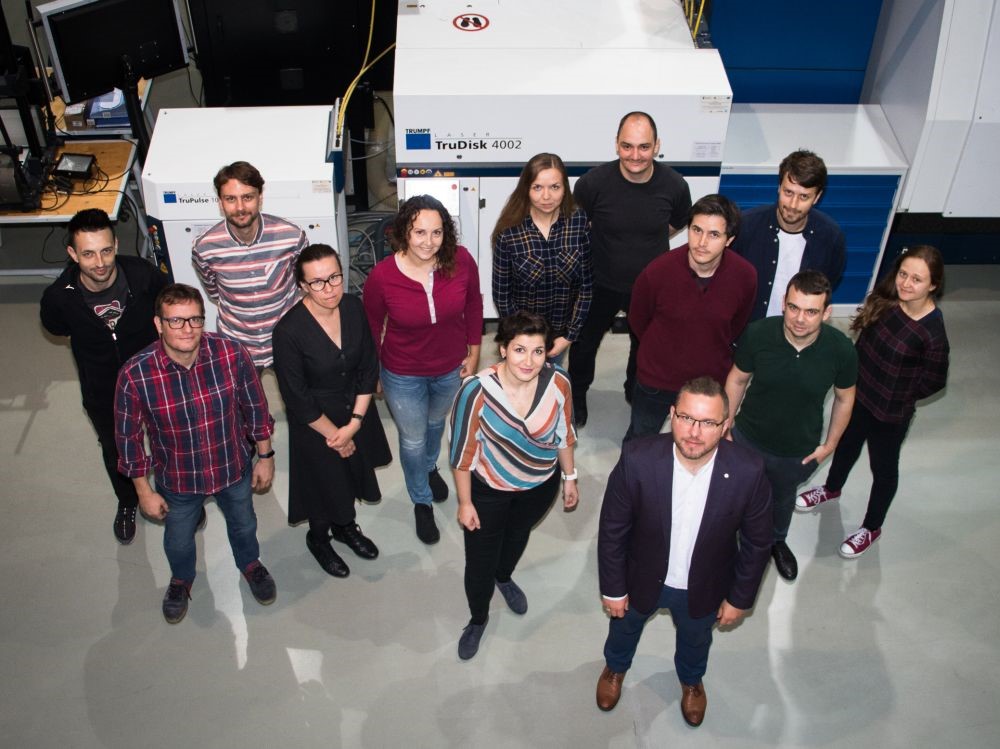

Meet our team

View the results of our work

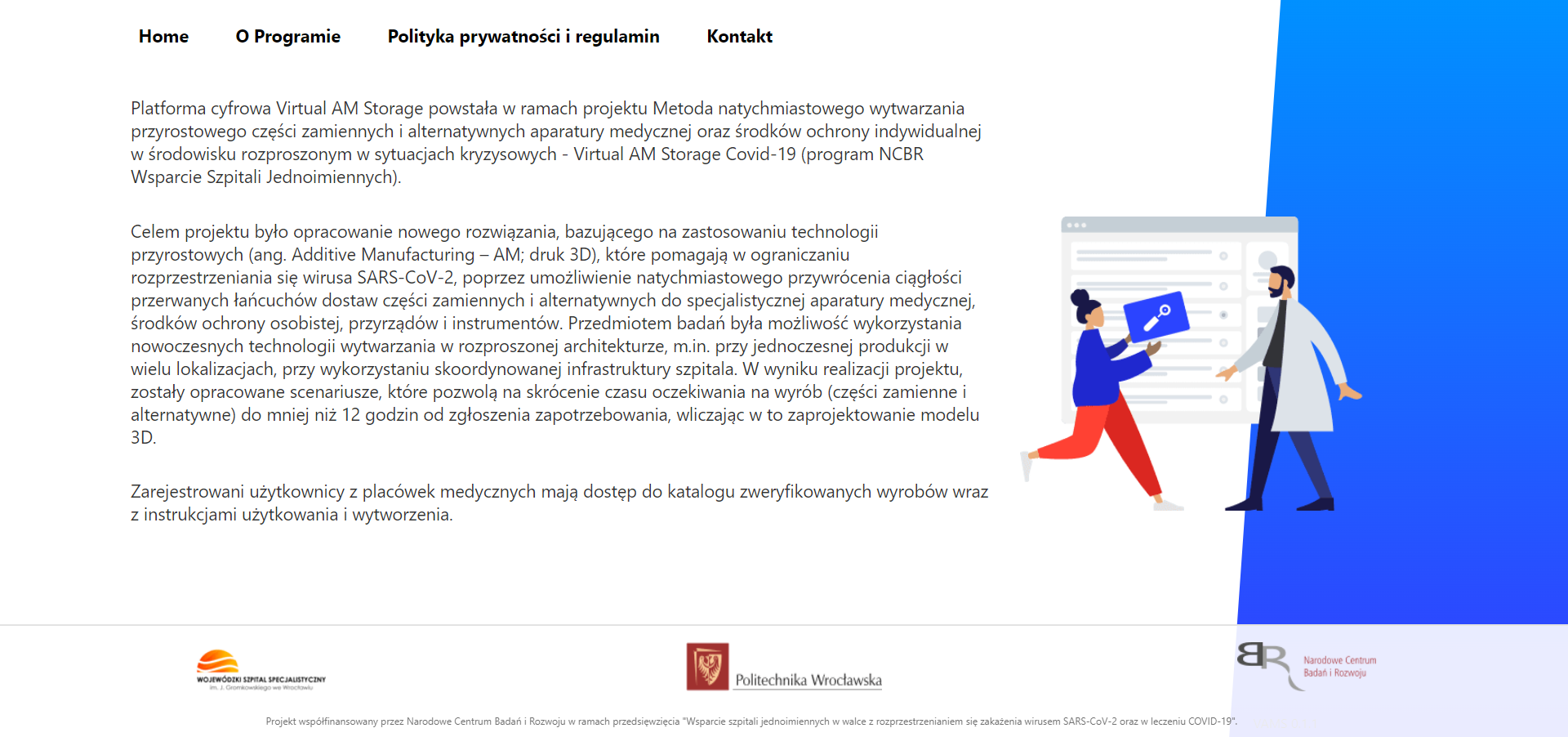

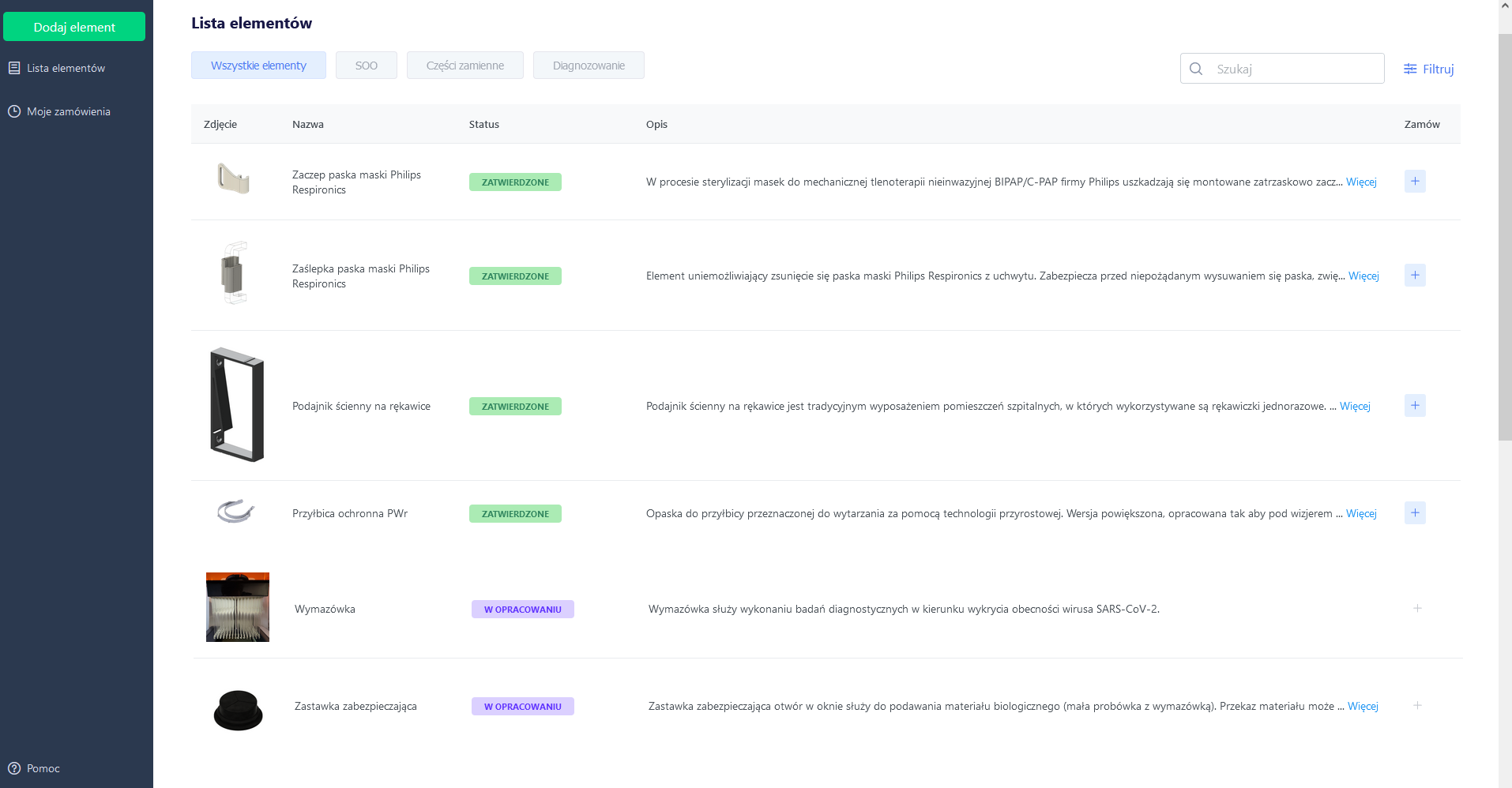

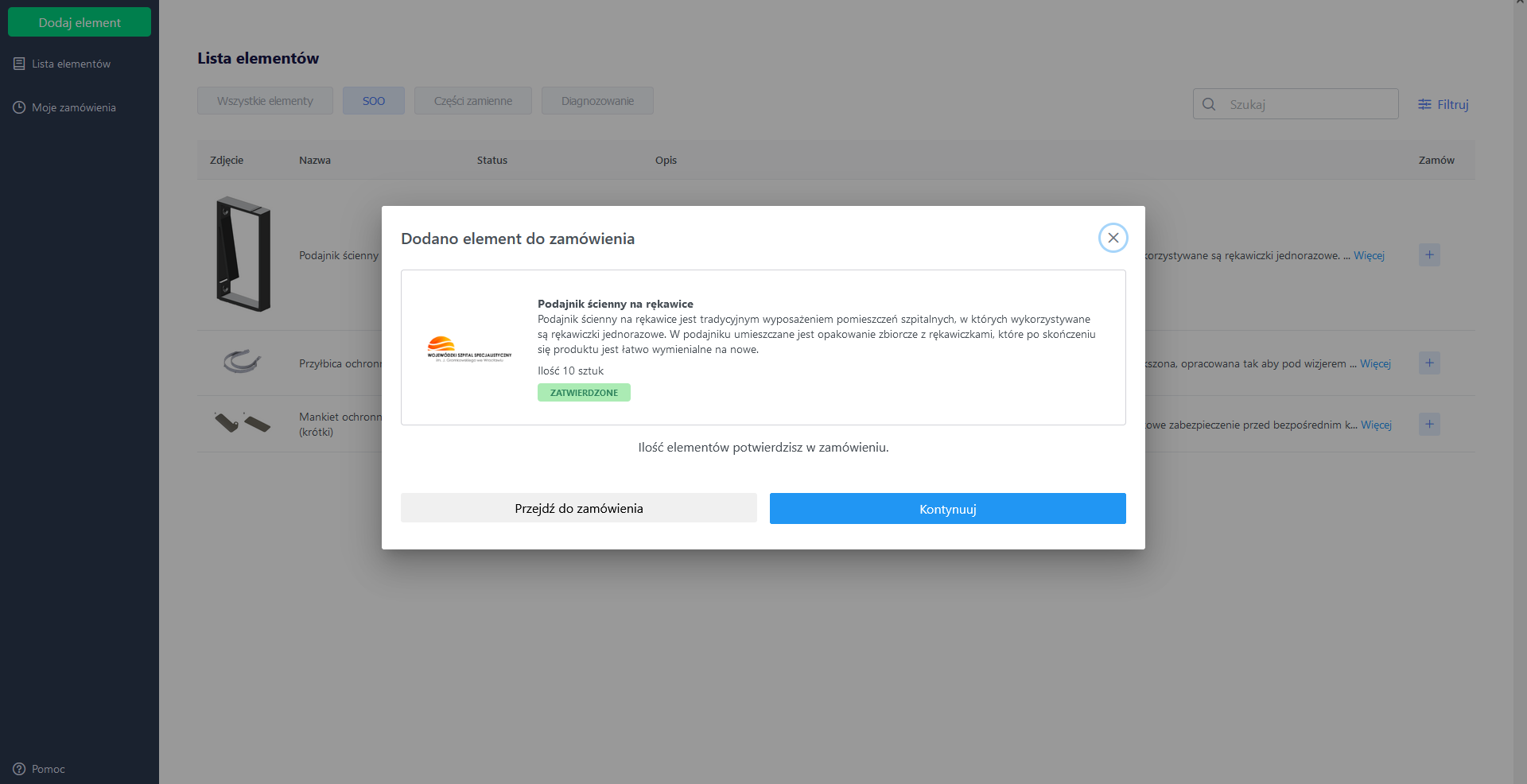

Of key utility value is the generally available digital platform developed as a result of the project. It enables efficient organization of scattered production in crisis situations, similar to the first waves of a pandemic.

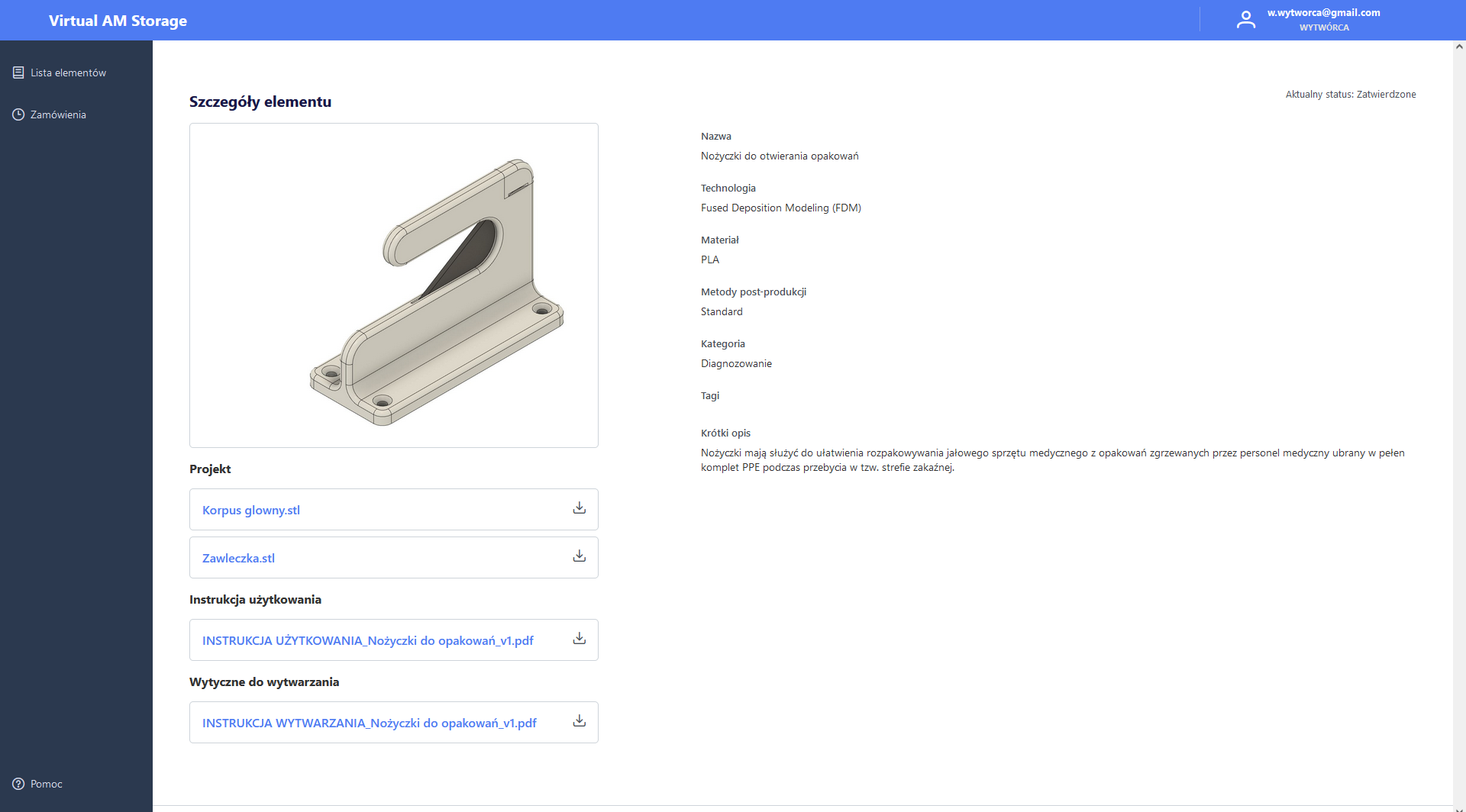

IT Platform - http://med3d.szpital.wroc.pl/ - represents the developed technology and contains a knowledge base in the form of instructions for use and the analysed demonstrators manufacturing instructions.

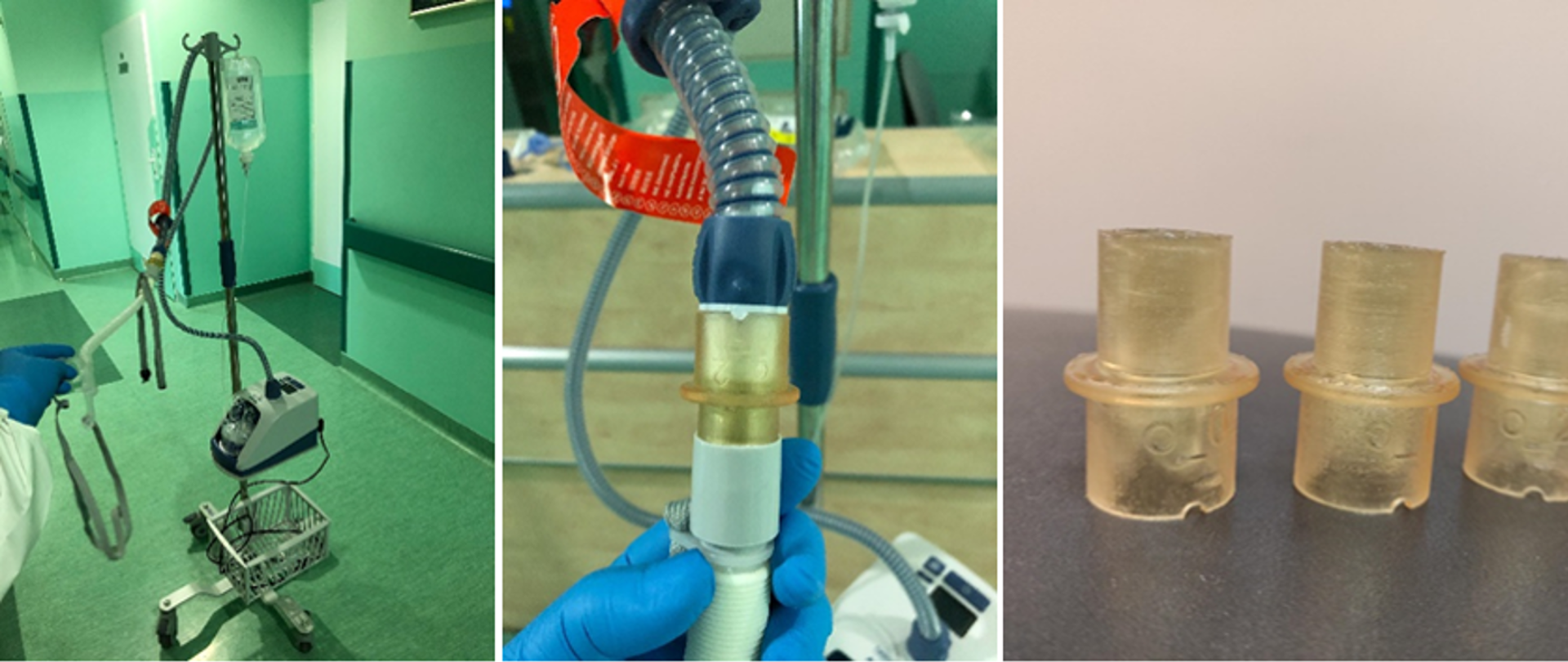

The developed demonstrators were divided into three groups (categories):

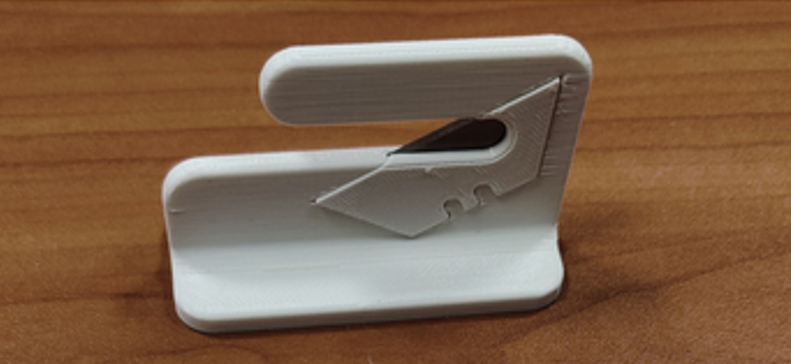

A – personal protective equipment (PPE),

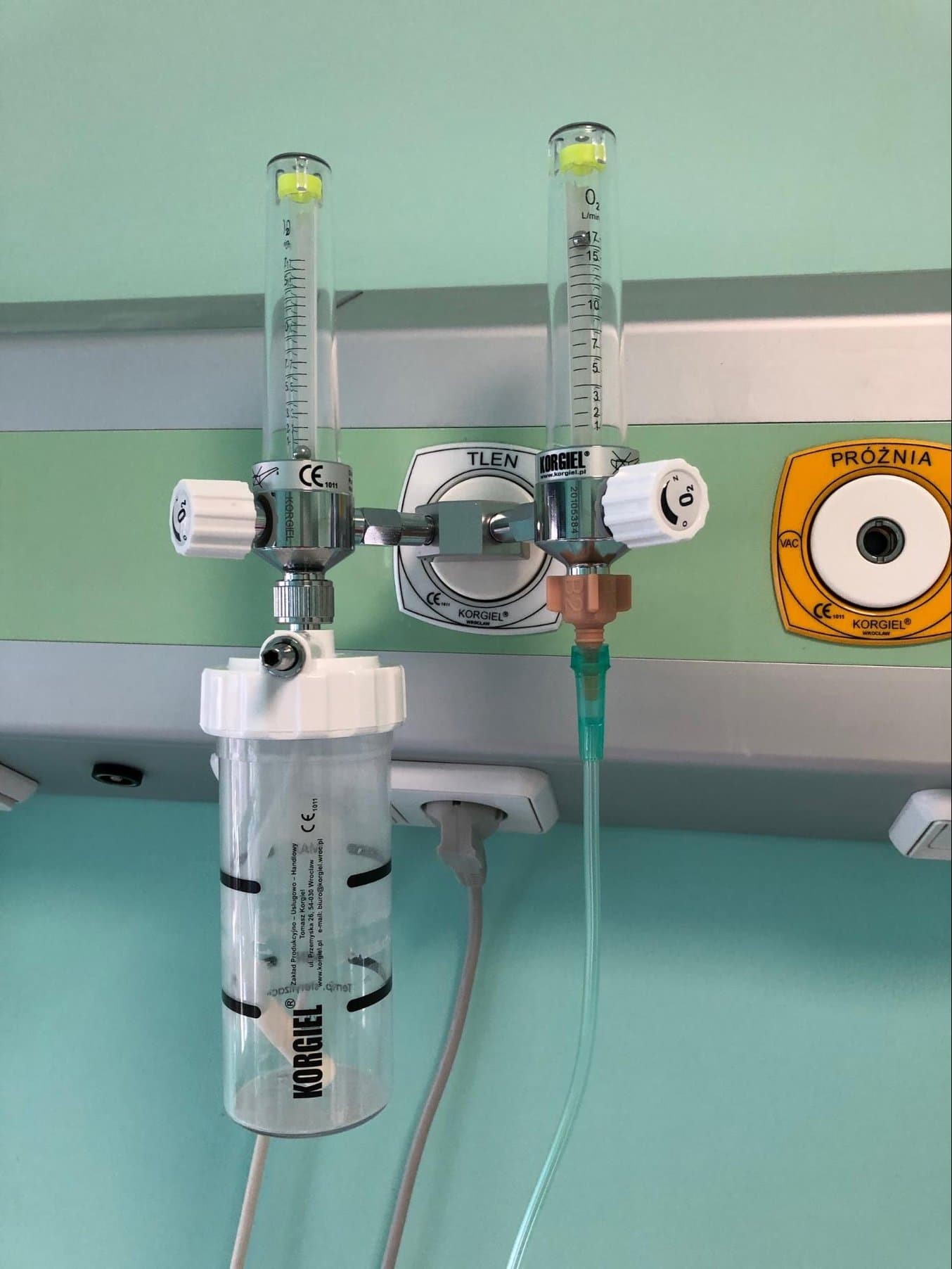

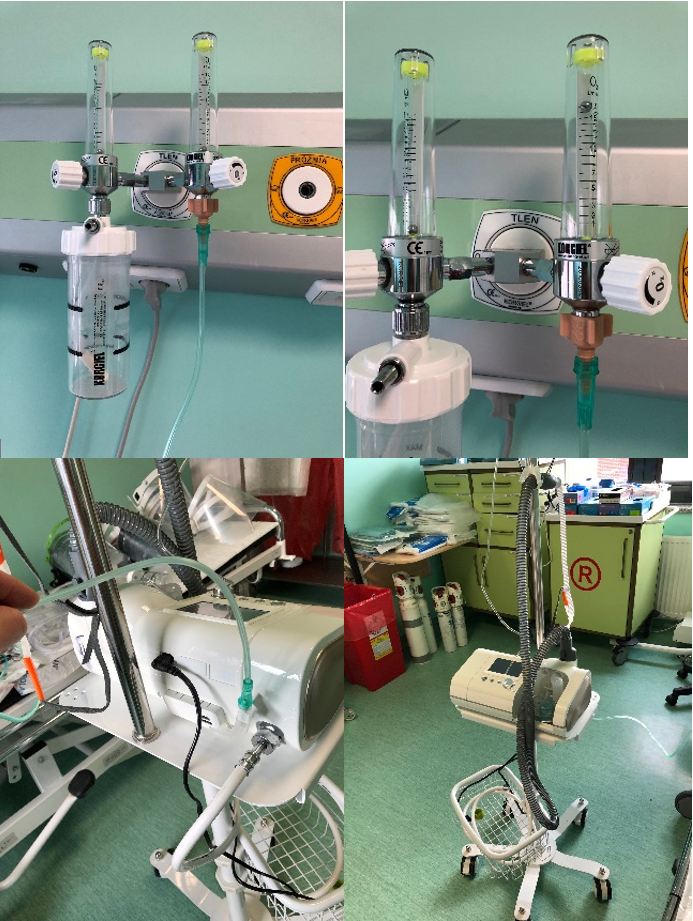

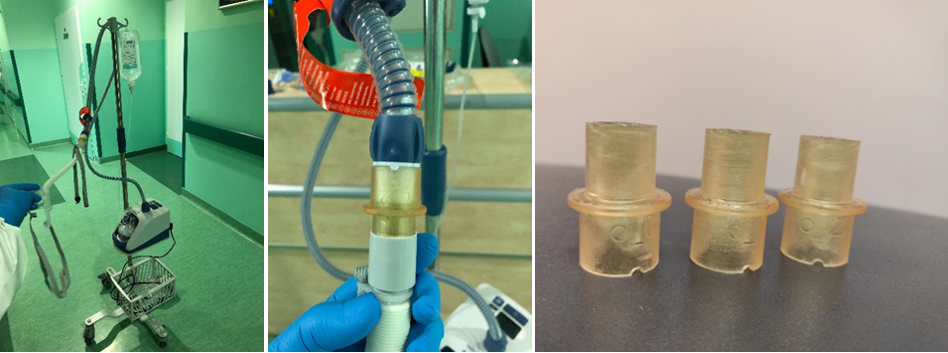

B – support for medical procedures,

C – diagnosing.

Moreover, in order to simplify and at the same time increase the efficiency of the tool, the functionality of the platform can be adapted to one of the user types - "hospital", "manufacturer" or "technology expert". The platform also has the option enabling submission of new ideas, which will be verified by experts, and a tool based on "machine learning" that allows you to assess the technological quality (i.e. suitability to the chosen technology) of the selected part.

What problem is addressed by the project?

The use of additive manufacturing in various industries enables the creation of virtual warehouses, where it is possible to store data on finished products intended for production and, if there is a demand for a particular detail, its virtual model along with information on manufacturing and its use is transferred directly to the contractor.

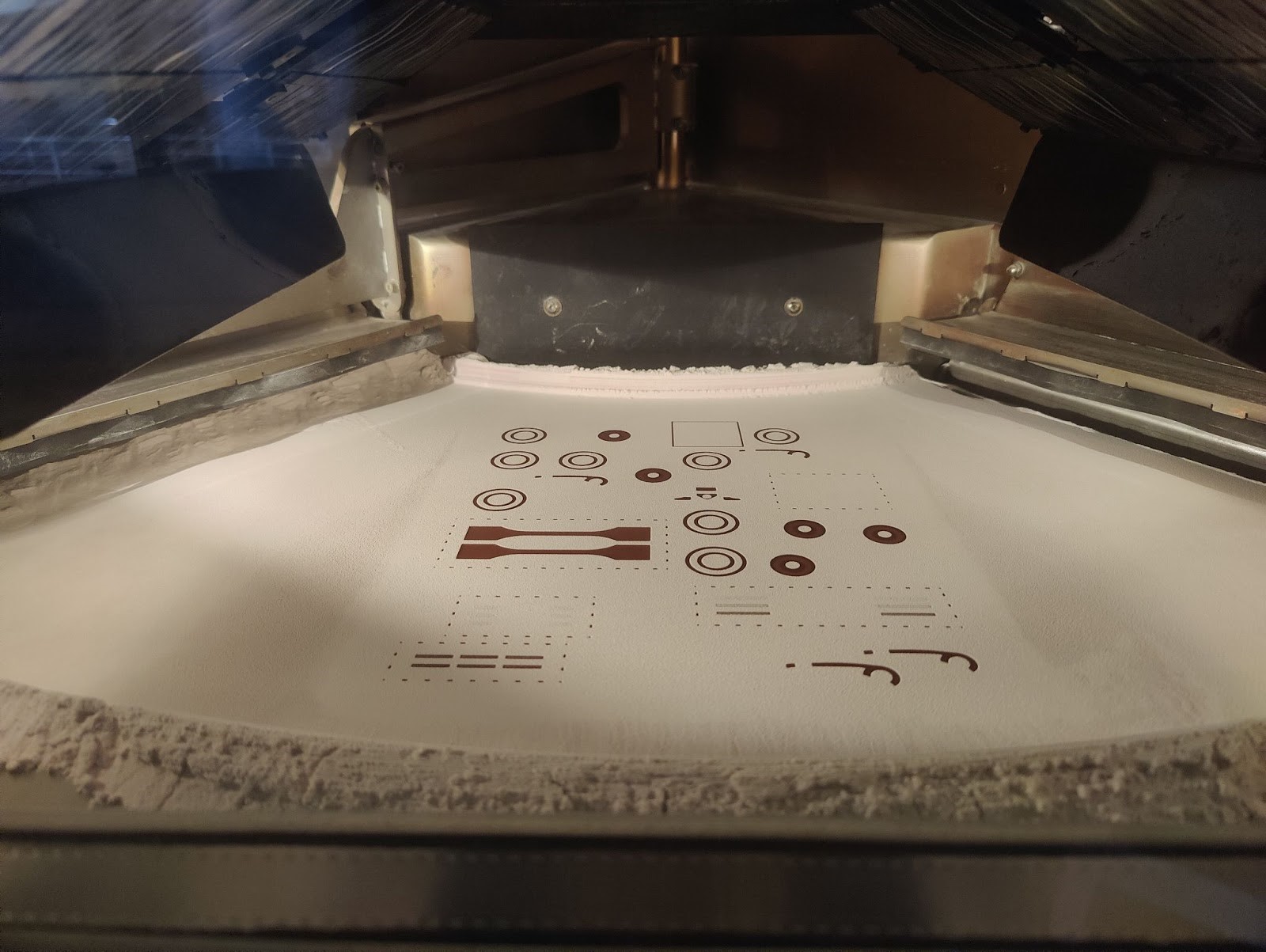

Due to the lack of clear-cut criteria and requirements relating to the quality of additively manufactured products, guidelines were developed and implemented within the international pilot digital platform. The platform serves, among others for analysing digital models and identifying spare parts for medical equipment as well as managing scattered production. The solution enables immediate replenishment (within up to 12 hours) of spare parts for medical equipment and personal protective equipment in crisis situations as a result of an interruption or overloading of the current supply chain

The use of the digital platform allows, among others to:

- quick ordering by hospitals and healthcare entities of the necessary spare parts or alternative medical equipment and PPE;

- verification of ideas - in terms of their technological quality, by a team of experts on additive techniques - for new solutions (spare or alternative parts) proposed by medical workers, paramedics and manufacturers (entrepreneurs, enthusiasts of "3D printing");

- expansion of the network of suppliers / manufacturers of spare parts, which in critical situations enables quick replenishment of spare parts, even in cases of large orders.

Who uses the project results?

The results of the project can be used by hospitals and companies involved in the production as well as research institutions and other entities operating in the "3D printing" industry. The digital platform developed under the project enables you to quickly start manufacturing the spare parts you need.

For hospitals and medical facilities, the platform is a kind of "online store" where they can quickly identify their needs and get what they are looking for - especially when normal supply chains are interrupted or overloaded

What was the greatest challenge during project implementation?

Development of the above-mentioned method in conditions of interrupted supply chains was associated with a number of challenges. The research group focused on:

- development of guidelines for the design and manufacture of medical equipment;

- determination of process parameters allowing to obtain high repeatability of products;

- cytotoxicity analysis and determination of the influence of antimicrobial additives on hospital pathogens, incl. S. aureus, P. aeruginosa, C. difficile, concerning both commercially available materials with bactericidal properties and newly developed materials with the addition of copper;

- selection of post-process and finishing processing;

- development of the logistics chain, starting with the selection of materials and techniques, all the way to the organization of deliveries and guidelines concerning packaging and use of the products.